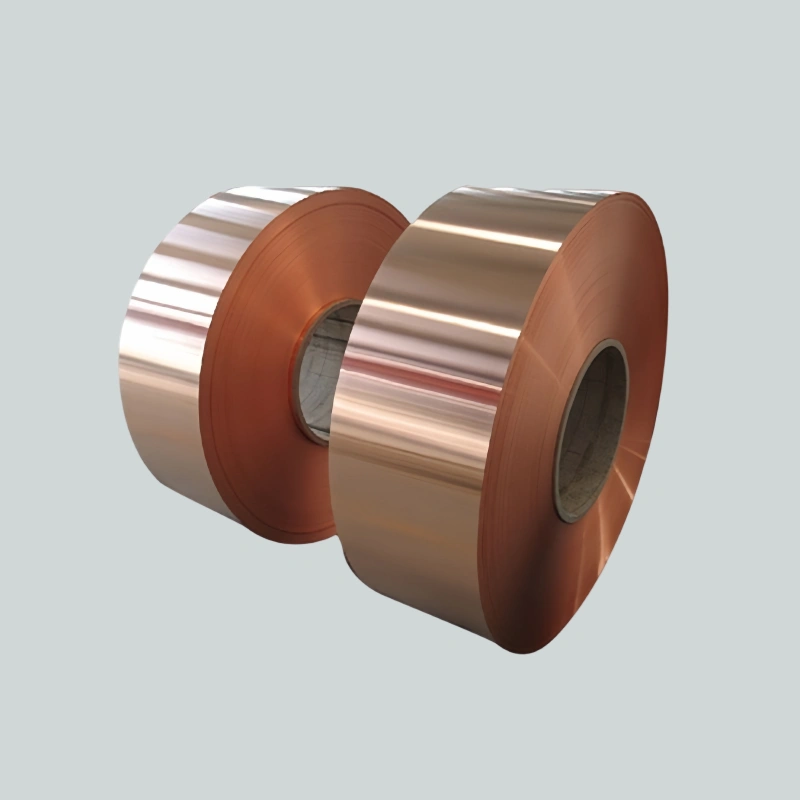

When seawater eats standard bronze valves in months and high-pressure steam systems demand leakproof seals, C92200 'Navy M' bronze answers the call. Developed during WWII for naval vessels, this leaded tin bronze (88% Cu, 6% Sn, 1.5% Pb, 4.5% Zn) withstands pounding waves and dezincification while machining like butter. ASTM B584-certified – it’s the unsung hero in shipboard fittings, power plant valves, and offshore systems demanding zero-failure performance.

TECH SPECS: MARINE-GRADE TOUGHNESS

(ASTM B584 / UNS C92200 / Military Spec QQ-B-750)

| Property | C92200 | C93200 | C90700 |

|---|

| Composition | 88% Cu, 6% Sn, 1.5% Pb, 4.5% Zn | 83% Cu, 7% Sn, 7% Pb | 89% Cu, 11% Sn |

| Tensile Strength | 330 MPa (48 ksi) | 310 MPa | 255 MPa |

| Pressure Integrity | Zero leaks @ 6.000 psi | Seals fail @ 4.500 psi | Seals fail @ 3.000 psi |

| Machinability | 90% (free-cutting) | 80% | 20% |

| Seawater Corrosion | 0.002 mm/yr | 0.08 mm/yr | 0.005 mm/yr |

| Thermal Conductivity | 62 W/m·K | 45 W/m·K | 52 W/m·K |

Certifications: ASTM B584. ASME SB584. MIL-B-17962. NACE MR0175

5 REASONS NAVIES TRUST IT SINCE 1944

Dezincification Proof

"Passes ASTM B858 Method A testing – 80-year service life in USS North Carolina saltwater lines."

Machining Champion

"Cuts 50% faster than tin bronzes – reduces valve manufacturing costs by 30%."

Pressure Titan

"Holds 10.000-psi steam in power plants without gland leaks (ASME Boiler Code compliant)."

Weld/Repairable

"Accepts bronze brazing for onsite repairs – unlike lead-free alternatives."

Cost Savior

"30% cheaper than nickel-aluminum bronzes with equal corrosion resistance in brackish water."

KEY FEATURES: ENGINEERED FOR REAL-WORLD ABUSE

Chip-Breaking Lead Particles: Prevents tool binding during high-speed CNC

Thermal Shock Resistance: Withstands 212°F ↔ 68°F cycles in tidal zones

Biofouling Resistance: Inhibits barnacle growth on seawater valves

Non-Sparking: Safe for fuel tank vents (MSHA/NEC Class I Div 2)

MANUFACTURING PROCESS: BATTLE-READY METAL

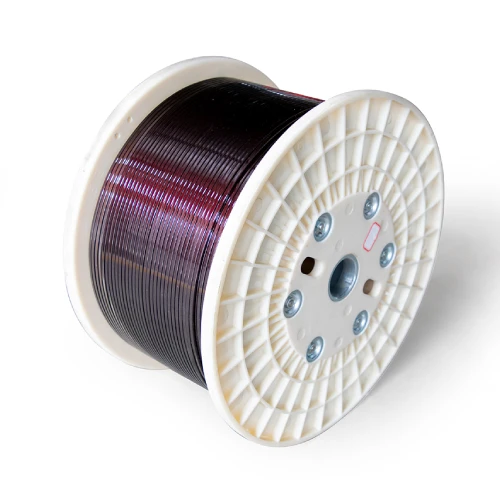

1 Induction Melting

"Copper-tin alloyed with controlled Pb/Zn additions (±0.15% chemistry control)."

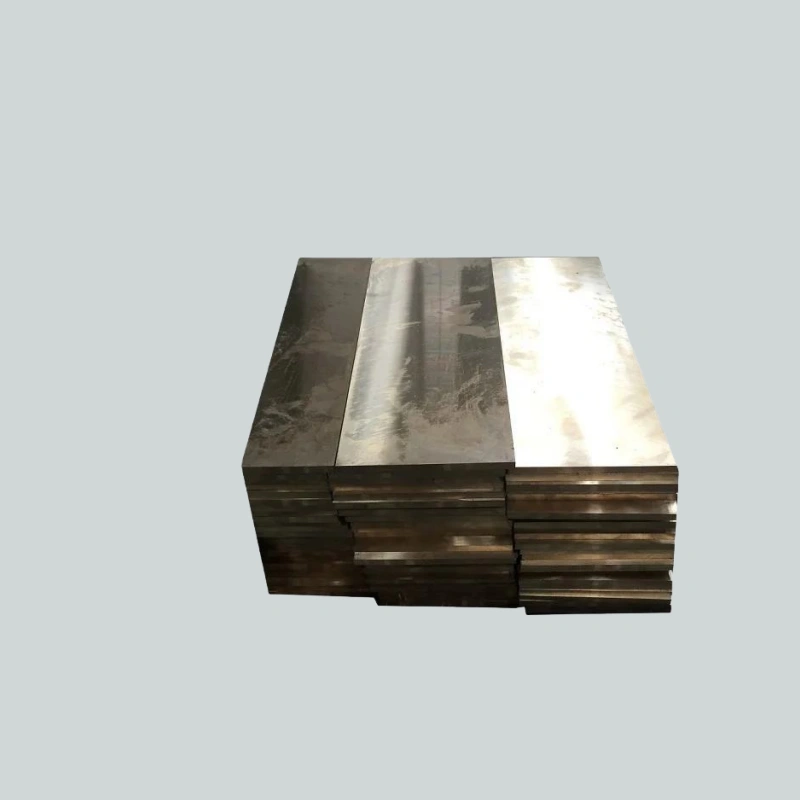

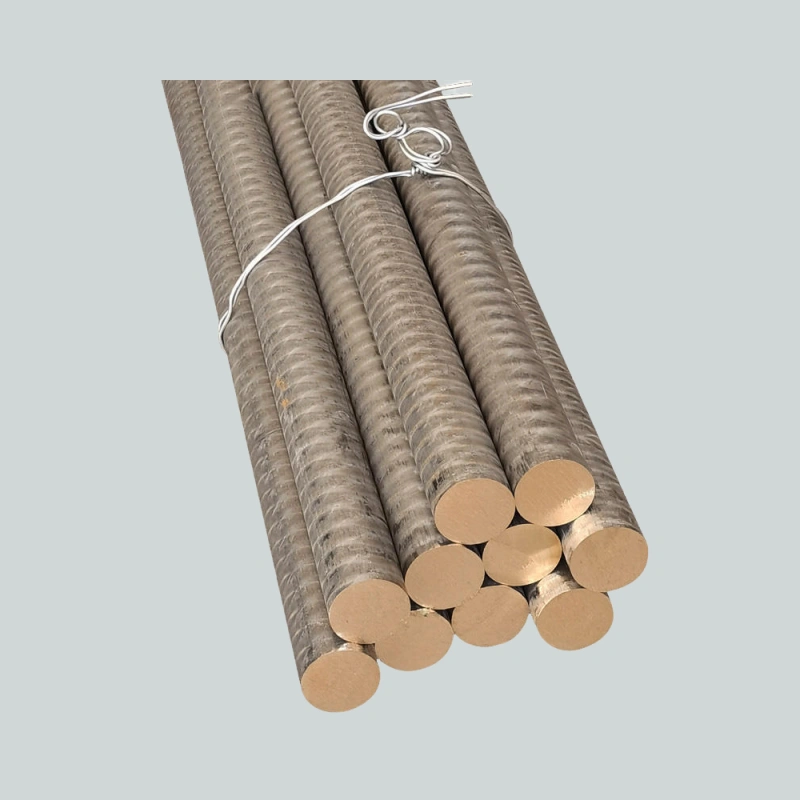

2 Continuous Casting

"Extruded rods/billets with uniform lead dispersion (ASTM E8 microstructure standards)."

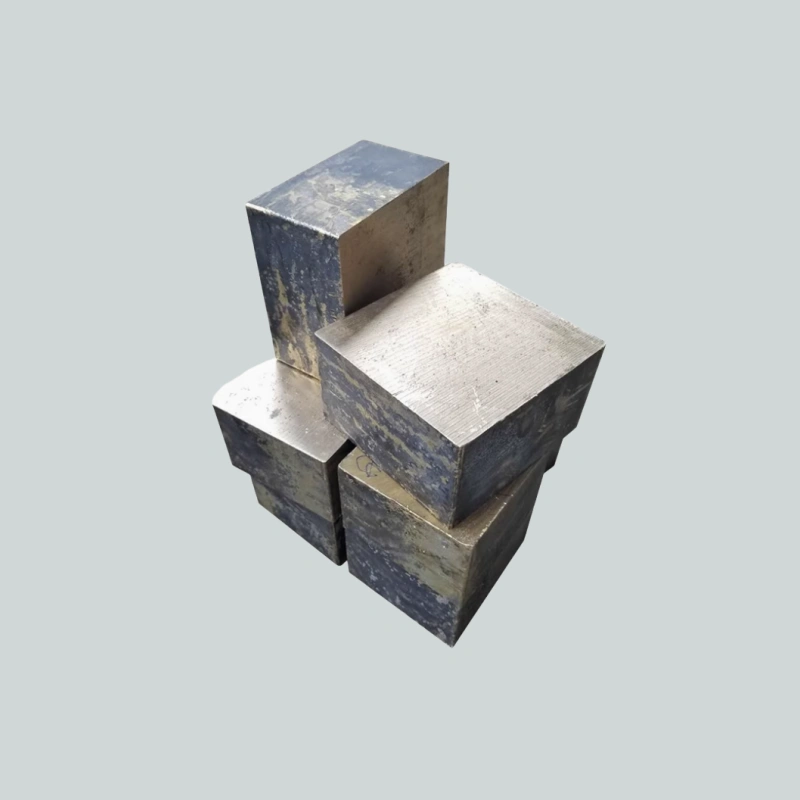

3 Hot Forging

"Forged valve bodies at 1450°F for directional grain flow (0% porosity)."

4 Machining Optimization

"Pre-tapped holes, grooved seats – ready for assembly without secondary ops."

WHERE IT DOMINATES: SALTY & STEAMY ENVIRONMENTS

| Industry | Critical Components | Performance Edge |

|---|

| Marine | Seawater valves, stern tube bushings | Zero dezincification after 15+ years |

| Power Gen | Steam condenser plates, turbine fittings | Handles 600°F thermal cycling |

| Waterworks | Pump impellers, fire hydrant stems | Resists chlorinated water pitting |

| Oil & Gas | Offshore platform riser flanges | Immune to sour gas cracking (NACE MR0175) |

| Industrial | Hydraulic valve blocks | Maintains 10µm surface finish after 1M cycles |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.