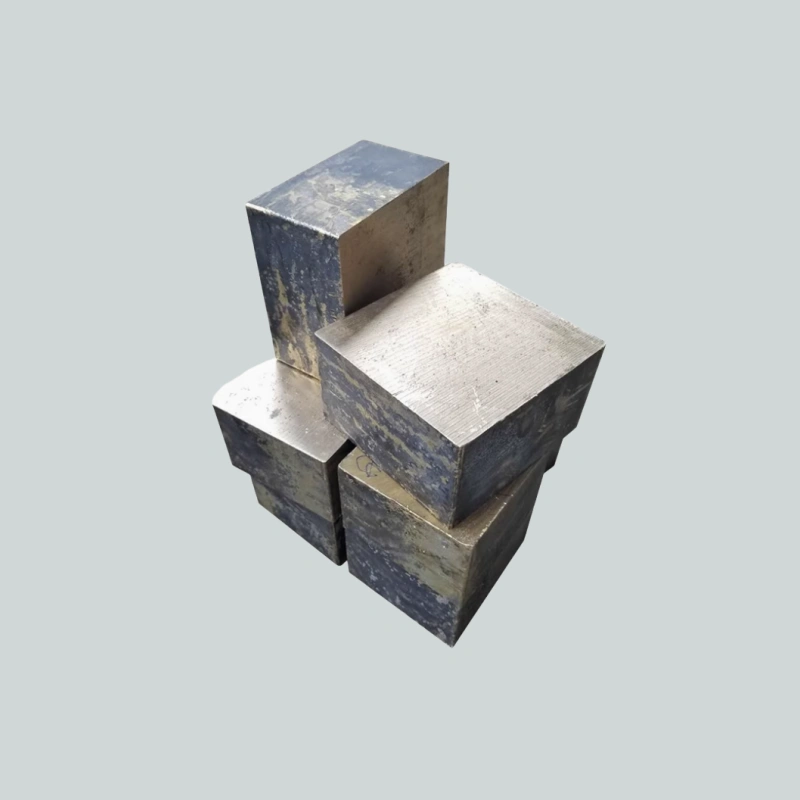

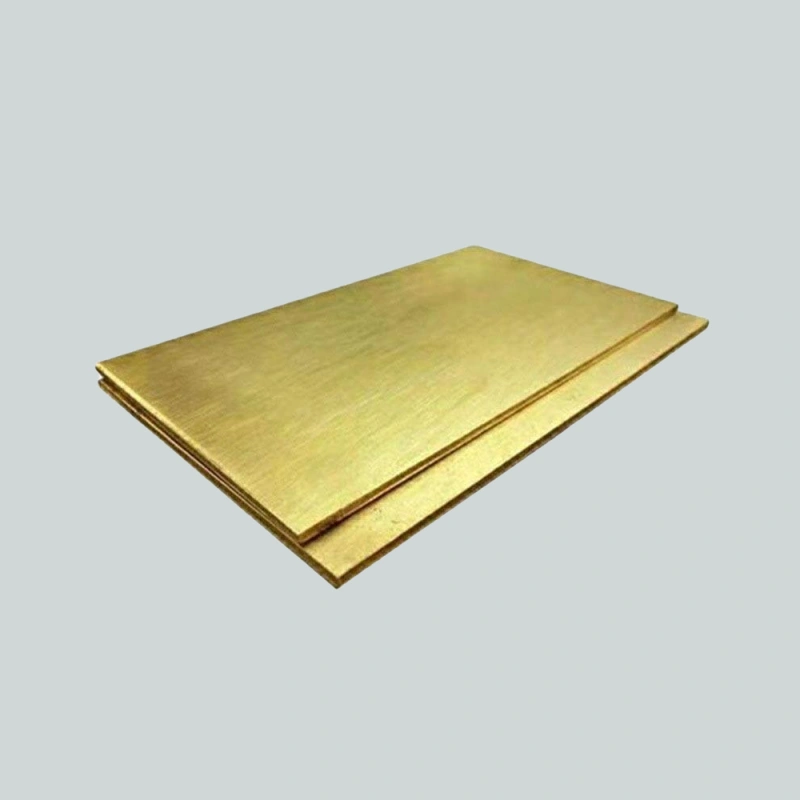

When seawater eats through stainless steel in a year and copper alloys crumble under load, C61000 Aluminum Bronze stands guard. This copper-aluminum-iron alloy (91% Cu, 7% Al, 2% Fe) laughs at salt spray while outlasting steels in brute strength. RoHS-exempt per Annex III 6c – it’s the backbone of offshore rigs, warships, and chemical plants where failure isn’t an option.

TECH SPECS: ENGINEERED FOR EXTREME ENVIRONMENTS

(ASTM B148 / UNS C61000 / RoHS Annex III Exempt)

| Property | C61000 | 316 Stainless | C95400 (Al-Bronze) |

|---|

| Composition | 91% Cu, 7% Al, 2% Fe | 16% Cr, 10% Ni | 85% Cu, 11% Al, 4% Fe |

| Tensile Strength | 586 MPa | 515 MPa | 758 MPa |

| Yield Strength (0.2%) | 207 MPa | 205 MPa | 379 MPa |

| Corrosion Rate | 0.001 mm/yr (Seawater) | 0.1 mm/yr | 0.002 mm/yr |

| Hardness | BHN 150 | BHN 150 | BHN 210 |

| Max Service Temp | 400°C | 870°C | 425°C |

Certifications: ASTM B148. ASME SB148. NACE MR0175. ABS Marine, RoHS Annex III 6c Exempt

5 REASONS INDUSTRY CHOOSES C61000

Seawater Immunity

"Zero pitting after 20+ years in tidal zones – outperforms 316 stainless by 8X in splash zones."

Cavitation Resistance

"Withstands propeller-induced bubble collapse – used in US Navy destroyer pump impellers since 2015."

Chemical Defense

"Resists sulfuric acid, ammonia, and sour gas (H₂S) – ideal for refinery valve stems."

Machinability Edge

"Cuts at 150 SFM with carbide tools – generates short chips, no built-up edge."

Lifetime Savings

"Eliminates replacement costs: lasts 4X longer than stainless in desalination plants."

KEY FEATURES: BEYOND THE DATA SHEET

Biofouling Resistance: Aluminum oxide layer prevents barnacle adhesion

Stress Corrosion Immunity: No cracking in chloride-rich environments

Thermal Conductivity: 59 W/m·K (3X stainless steel) for heat exchanger efficiency

Non-Sparking: Safe for explosive atmospheres (ATEX, IECEx certified)

PRECISION PROCESSING: FROM METAL TO MASTERPIECE

1 Controlled Alloying

"Induction-melted under argon shield – iron additions precisely timed to form κ-phase hardening."

2 Sand Casting

"Poured into resin-bonded molds for complex shapes (valve bodies, impellers) with ±1.5% tolerance."

3 Heat Treatment

"Solution annealed at 790°C + air quench for optimal corrosion-fatigue balance."

4 Quality Lockdown

"Liquid penetrant tested for defects; PMI-verified chemistry per EN 10204 3.1."

WHERE IT RULES: INDUSTRY APPLICATIONS

| Industry | Critical Components | Why C61000? |

|---|

| Marine | Propeller shafts, seawater valves | Immune to dezincification & cavitation |

| Oil & Gas | Wellhead components, pump casings | H₂S-resistant, NACE MR0175 compliant |

| Chemical | Heat exchanger tubes, reactor fittings | Handles acids/alkalis at 200°C+ |

| Power | Condenser tubes, turbine blades | Resists steam erosion & ammonia attack |

| Water Treatment | Desalination plant fittings | Survives 50.000+ hours in brine |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.