Product Parameters

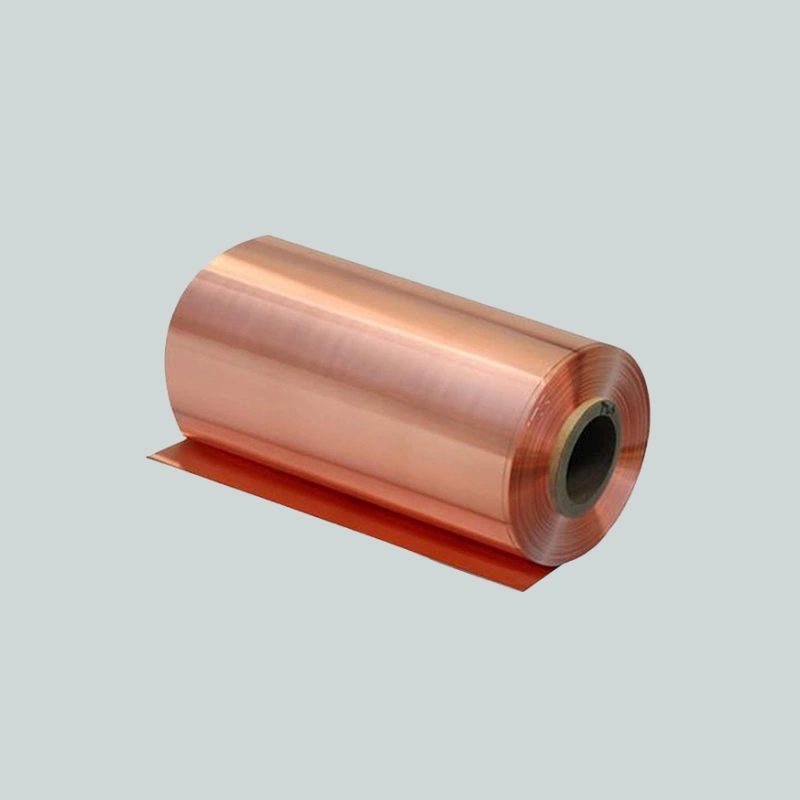

Conductor Material: 99.95% pure copper (ETP grade) or 99.7% aluminum (1060/1350 series)

Dimensions:

Width: 1.0mm – 15.0mm

Thickness: 0.2mm – 5.0mm

Insulation Thickness: 0.03mm – 0.2mm (single/multi-layer options)

Insulation Class: Class 180 (H), Class 200 (N), Class 220 (R) (polyimide, polyesterimide, or polyurethane coatings)

Tensile Strength: Copper core ≥ 205 MPa; Aluminum core ≥ 90 MPa

Elongation: ≥ 15% (copper); ≥ 12% (aluminum)

Breakdown Voltage: ≥ 2.5kV (single layer); ≥ 5kV (double layer)

Standards Compliance: IEC 60317. NEMA MW 1000. GB/T 6109

Product Advantages

Space Efficiency: Flat shape reduces winding volume by 20-30% compared to round wire, enabling more compact device designs.

Thermal Performance: Thin, high-grade enamel insulation (e.g., polyimide) withstands continuous operating temperatures up to 220°C, preventing overheating.

Conductivity Balance: Copper versions offer 98% IACS conductivity for high-efficiency applications; aluminum options provide 61% IACS with 30% weight savings.

Mechanical Durability: Enamel coating resists abrasion, solvents, and moisture, ensuring long-term reliability in harsh environments.

Cost Flexibility: Aluminum variants lower material costs by 40-50% without sacrificing basic performance, ideal for budget-sensitive projects.

Product Features

Uniform Insulation: Precision coating ensures consistent thickness (±0.005mm) for reliable dielectric strength.

Edge Treatment: Rounded corners minimize insulation stress during winding, reducing risk of cracking.

Adhesion Strength: Enamel bonds tightly to conductor, resisting peeling during bending or thermal cycling.

Solderability: Specialized coatings (e.g., polyurethane) allow direct soldering without stripping insulation.

Customizability: Available in bare, tin-plated, or annealed forms with tailored hardness for specific winding needs.

Product Process

Conductor Preparation: Copper/aluminum rods are rolled into flat strips, then annealed to adjust ductility.

Surface Cleaning: Chemical etching removes oxides, ensuring strong enamel adhesion.

Enamel Coating: Multiple layers of liquid enamel (dip or spray application) are applied, with each layer cured at 350-450°C in a vertical furnace.

Cooling & Sizing: Controlled cooling prevents enamel cracking; precision rolling ensures exact dimensions.

Quality Checks: Each batch undergoes dielectric testing, adhesion tests, and dimensional verification.

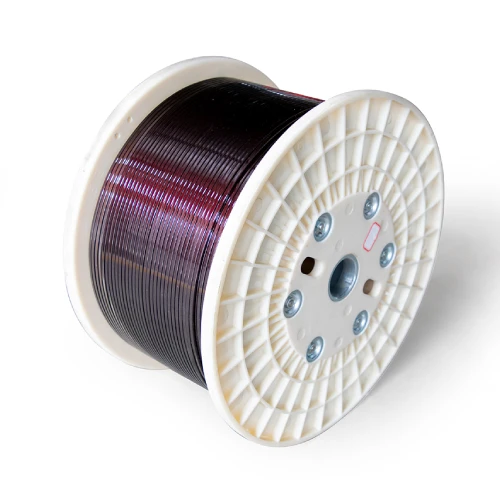

Spooling: Wound onto plastic or metal spools (10-50kg capacity) for easy handling during winding operations.

Main Application Fields

Electrical Motors: High-efficiency AC/DC motors (e.g., EV traction motors, industrial pumps) where space and heat management are critical.

Transformers & Inductors: Power transformers, planar inductors, and choke coils requiring compact windings.

Generators: Alternators in automotive, marine, and power generation systems.

Appliances: Compressors, fans, and HVAC motors in refrigerators, air conditioners, and washing machines.

Renewable Energy: Wind turbine generators, solar inverter transformers, and energy storage system components.

Aerospace & Automotive: Lightweight aluminum versions for aircraft actuators; high-temperature copper variants for EV battery management systems.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.