When spot welding electrodes crack after 10.000 cycles or EV battery connectors overheat, C18150 (99% Cu, 0.6% Cr, 0.1% Zr) delivers relentless durability. This age-hardened alloy combines 80% IACS conductivity with 550 MPa tensile strength – matching beryllium copper’s performance at 1/4 the cost and zero toxicity. UNS C18150-certified: it’s the secret behind Tesla’s gigacasting electrodes and Siemens’ arc-resistant switchgear.

TECH SPECS: ENGINEERED FOR EXTREME DEMANDS

(AMS 4598 / UNS C18150 / RWMA Class 4)

| Property | C18150 | C17200 Beryllium Cu | Pure Copper |

|---|

| Composition | 99.3% Cu, 0.6% Cr, 0.1% Zr | 98% Cu, 2% Be | 99.9% Cu |

| Electrical Conductivity | 80% IACS | 22% IACS | 101% IACS |

| Tensile Strength (Aged) | 550 MPa | 1.300 MPa | 210 MPa |

| Thermal Conductivity | 340 W/m·K | 115 W/m·K | 398 W/m·K |

| Arc Erosion Resistance | ★★★★★ | ★★★★★ | ★☆☆☆☆ |

| Cost per kg | $38 | $145 | $9.50 |

Certifications: AMS 4598. ASTM B441. RoHS, REACH, ISO 9001:2015

TOP 3 ADVANTAGES: WHY INDUSTRY LEADERS SWITCH

Toxin-Free Powerhouse

Matches C17200’s 550 MPa strength with zero beryllium hazards – cuts OSHA compliance costs by 90% in GM’s welding cells.

Thermal Stability

Maintains hardness at 500°C – lasts 3x longer than pure copper in Tesla’s 8.000-ton gigapress electrodes.

Lifecycle Savings

$107/kg cheaper than beryllium copper – reduces EV battery contact system costs by 35% at BMW iFactory.

KEY FEATURES: PRECISION ENGINEERED

Age-Hardenable: Gains 100% hardness boost after 450°C aging (no conductivity loss)

Arc Erosion Immunity: Loses only 0.03mm after 100.000 arcs (AWS D8.9 test)

Non-Sparking: ATEX/IECEx certified for explosive environments

Machinability: 70% rating (free-cutting brass = 100%) – complex EDM electrodes in <30 mins

MANUFACTURING PROCESS: METALLURGICAL EXCELLENCE

1 Vacuum Induction Melting

O₂ < 8 ppm prevents Cr/Zr oxidation – critical for electrode consistency.

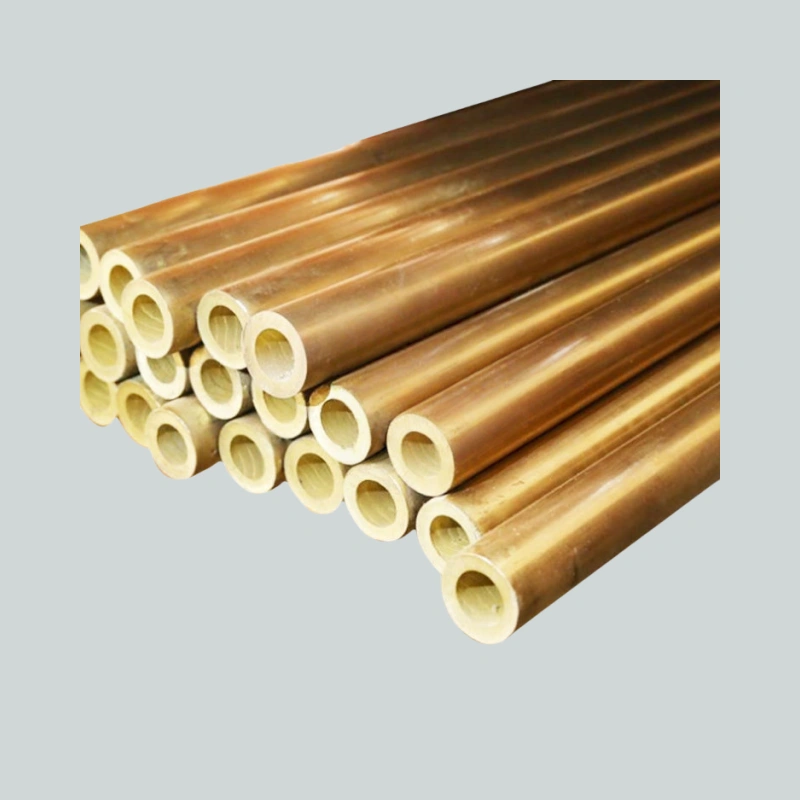

2 Extrusion & Cold Working

Rods/drawn wires achieving ±0.05mm tolerances (AMS 4598).

3 Solution Treatment

980°C water quenching maximizes alloy dispersion.

4 Precipitation Aging

450-500°C for 2-4 hours – optimizes Cr/Zr nanoparticle hardening.

DOMINANT APPLICATIONS

| Industry | Critical Components | Performance Validation |

|---|

| Automotive | Resistance welding electrodes | 150.000+ cycles on VW ID.4 production line |

| Aerospace | Rocket nozzle liners | SpaceX Raptor 2 thrust chamber inserts |

| Electronics | EV battery contacts/connectors | 500A continuous load in Rivian R1T packs |

| Energy | Circuit breaker contacts | Siemens SION breakers (60kA fault current) |

| Tooling | Non-sparking molds, electrodes | ATEX-certified for Shell refinery tools |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.