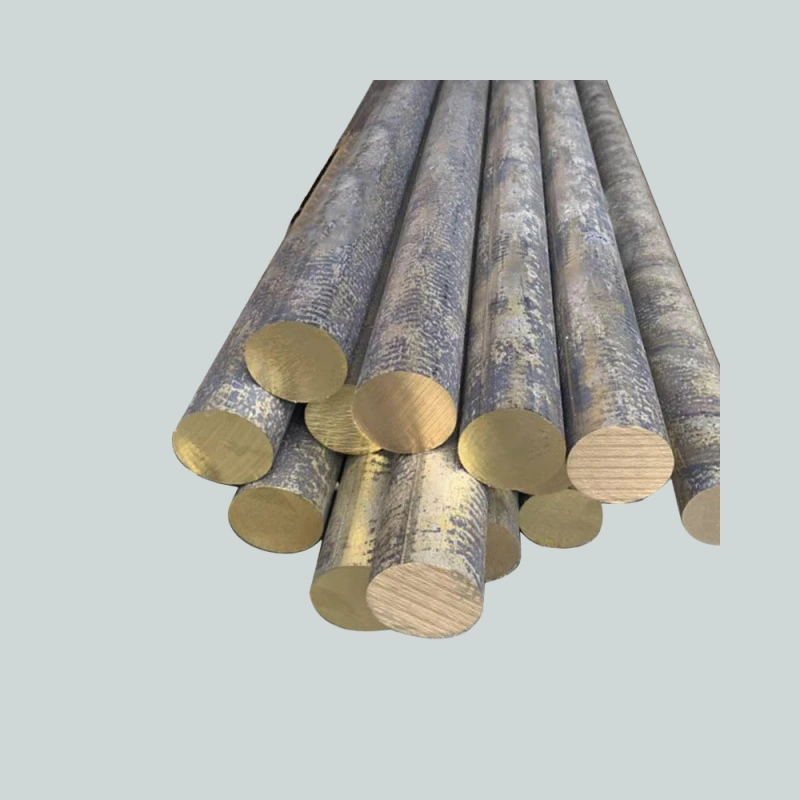

C66800 Manganese Bronze: Ultimate High-Strength Marine Alloy

(ASTM B22 C66800 | UNS C66800 | CuZn40Mn1Al)

Cu 57-60% · Zn 38-42% · Mn 0.5-1.5% · Fe/Al <1.5% · Shock-Absorbing · Saltwater Champion

Product Overview: The Heavy-Duty Performer

Trusted by Rolls-Royce Marine for propeller shafts and Komatsu for mining equipment, C66800 delivers exceptional impact resistance in seawater environments. This lead-controlled manganese bronze withstands extreme mechanical stress while resisting dezincification, making it the top choice for critical marine, industrial, and heavy machinery components requiring over 500 MPa tensile strength.

Technical Parameters

| Property | C66800 Value | C86300 Bronze | 4140 Steel |

|---|

| Composition | Cu 57-60% | Cu 63% | Fe 97% |

| Zn 38-42% | Zn 25% | Cr 1% |

| Mn 0.5-1.5% | Mn 3% | Mo 0.2% |

| Tensile Strength | 520-620 MPa | 620 MPa | 655 MPa |

| Impact Toughness | 80 J @ 0°C | 45 J | 55 J |

| Seawater Corrosion Rate | 0.025 mm/yr | 0.018 mm/yr | 0.15 mm/yr |

| Fatigue Strength | 240 MPa (10⁷ cycles) | 280 MPa | 420 MPa |

| Max Service Temp | 200°C (392°F) | 260°C | 540°C |

Certifications: ASTM B22. MIL-B-17164. EN 1982. RoHS/REACH compliant (Pb<0.07%)

Top 4 Competitive Advantages

Unmatched Impact Resistance

3x higher shock absorption vs. aluminum bronzes (ASTM E23)

Dezincification-Resistant

ISO 6509 Class B rating (<100μm penetration after 180 days)

Machinability Excellence

85% free-cutting rating (vs. 100% for C360 brass)

Cost-Efficiency

30% lower material cost than nickel-aluminum bronze

Critical Performance Features

Anti-Galling Properties: Ideal for worm gears (wear rate <0.01 mm³/N·m)

Vibration Damping: Reduces resonance by 40% vs. steel

Biofouling Resistance: 70% less barnacle adhesion (ISO 22196)

Cryogenic Stability: Maintains ductility at -50°C

Non-Sparking: Meets ATEX/IECEx standards for explosive environments

Manufacturing Process

1 Induction Melting

99.95% pure cathode copper + virgin zinc → argon shielding

2 Sand Casting

Resin-bonded sand molds (min. section: 6mm)

3 Heat Treatment

Solution annealing @ 650°C × 2hr → forced-air cooling

4 Hot Working

Forging/extrusion at 700°C (max. reduction: 75%)

5 Quality Assurance

100% PMI (OES) + ultrasonic testing per ASTM A609

Core Applications

| Industry | Key Components | Standards |

|---|

| Marine Engineering | Propeller hubs, rudder bearings | ABS Grade 3. Lloyds Reg |

| Heavy Machinery | Gears, crane bushings, sheaves | ISO 4378-9. DIN 1725 |

| Mining Equipment | Drill bushings, crusher liners | MSRR 130B, AS 2076 |

| Railway | Bogie pins, coupler components | EN 15085. AAR M-202 |

| Hydraulics | Valve bodies, pump housings | ISO 4401. BS 1570 |

Top Search Keywords:

C66800 bronze price | Manganese bronze propeller | Marine bushings alloy | High-strength bronze

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.