Product Parameter

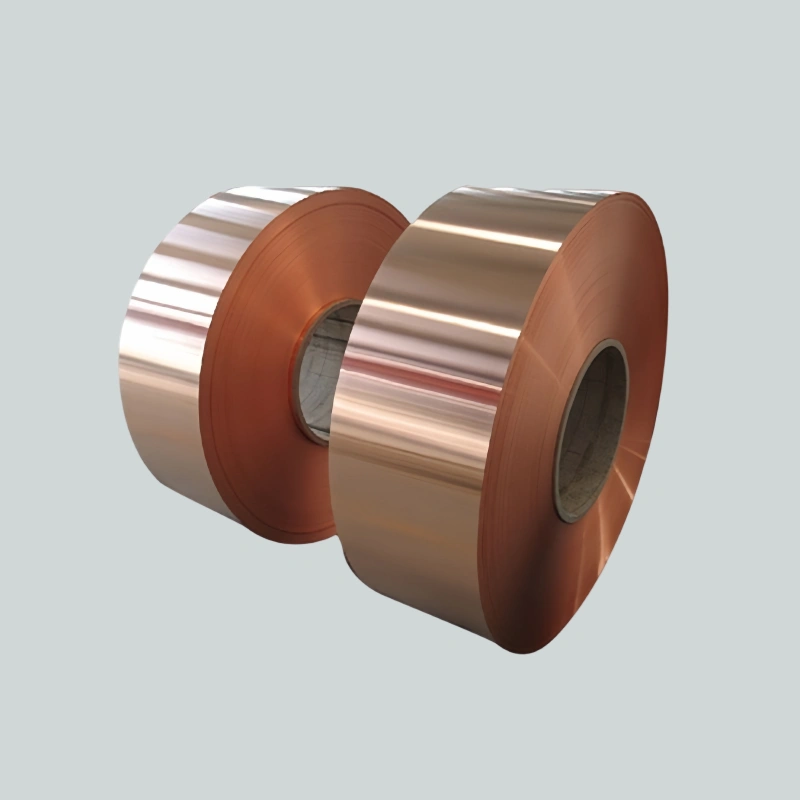

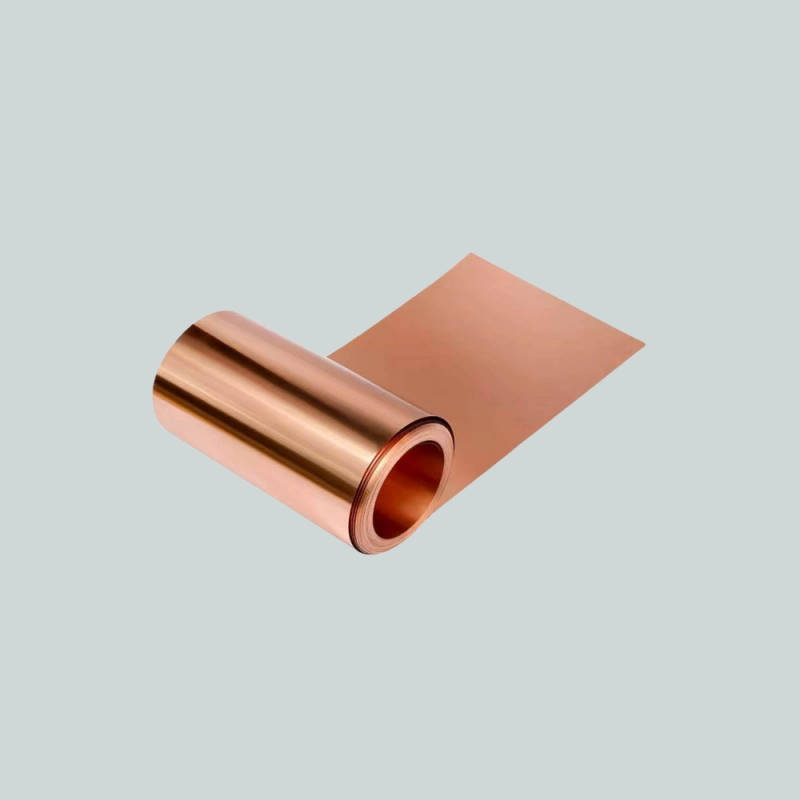

Copper strip

Thickness range: 0.08 mm to 3.0 mm, typical specifications include 0.5 mm, 0.8 mm, 1.0 mm, 1.2 mm, 2.0 mm, etc.

Width range: 8 mm to 1250 mm, the specific width can be adjusted according to standard or customized requirements.

International Standards

ASTM Standards:

Copper Strip: Thickness tolerance refers to ASTM B152, for example, when the thickness is ≤0.1 mm, the tolerance is ±0.012 mm.

EN Standards:

Copper Plate/Copper Strip follows EN 1652 (corresponding to DIN 1787), with thickness ranging from 0.006 mm to 50 mm, and width graded by thickness (e.g. 0.5-0.8 mm width ≤600 mm).

GB/T Standards:

Copper Strip implements GB/T 2059, with a thickness range of 0.5-0.8 mm, a width tolerance of ±0.1 mm, and a condition of O60 (soft state).

Chemical composition

| Grade | Cu (Copper) | Other Main Elements and Their Contents | Impurity Contents |

|---|

| C10100 | ≥99.97% | - | Total ≤ 0.03% |

| C10200 | ≥99.95% | - | Total ≤ 0.05% |

| C11000 | ≥99.90% | - | Total ≤ 0.10% |

| C12000 | ≥99.90% | P: 0.004% - 0.012% | Total ≤ 0.10% |

| C12200 | ≥99.90% | P: 0.015% - 0.040% | Total ≤ 0.10% |

| C14500 | ≥99.0% | Te: 0.4% - 0.7% | Total ≤ 1.0% |

| C17200 | Remainder | Be: 1.80% - 2.0%, Co or Ni: A small amount | Total ≤ 0.5% |

| C17500 | Remainder | Be: 0.4% - 0.7%, Co: 1.4% - 2.2% | Total ≤ 0.5% |

| C17510 | Remainder | Similar to C17500, with slight differences in composition | Total ≤ 0.5% |

| C18150 | Remainder | Cr: 0.4% - 1.0%, Zr: 0.08% - 0.25% | Total ≤ 0.5% |

| C18200 | Remainder | Cr: Approximately 1.0%, P: 0.002%, Mn: 0.0005%, As: 0.0002%, Si: 0.05%, Fe: 0.045%, Mg: 0.0006%, Sn: 0.0065%, Al: 0.0010%, Bi < 0.0001% | Total ≤ 0.5% |

| C70600 | 88.0% - 90.0% | Ni: 9.0% - 11.0%, Fe: 1.0% - 1.8%, Mn ≤ 0.5%, Si ≤ 0.5%, S ≤ 0.05%, P ≤ 0.05% | Total ≤ 0.5% |

| W70Cu3 | 30% | W: 70% | Total impurity content < 0.5% |

| W75Cu2 | 25% | W: 75% | Total impurity content < 0.5% |

| W80Cu2 | 20% | W: 80% | Total impurity content < 0.5%

|

Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|

| C10100 | ≥205 | ≥69 | ≥45 | 40 - 60 |

| C10200 | ≥205 | ≥69 | ≥45 | 40 - 60 |

| C11000 | ≥220 | ≥76 | ≥40 | 45 - 65 |

| C12000 | ≥220 | ≥76 | ≥40 | 45 - 65 |

| C12200 | ≥220 | ≥76 | ≥40 | 45 - 65 |

| C14500 | ≥240 | ≥103 | ≥30 | 60 - 80 |

| C17200 | After heat treatment

≥1100 | After heat treatment

≥1035 | ≥3 | 360 - 420 |

| C17500 | After heat treatment

≥725 | After heat treatment

≥620 | ≥4 | 240 - 300 |

| C17510 | After heat treatment

≥690 | After heat treatment

≥585 | ≥5 | 220 - 280 |

| C18150 | ≥380 | ≥275 | ≥15 | 100 - 130 |

| C18200 | ≥380 | ≥275 | ≥15 | 100 - 130 |

| C70600 | ≥370 | ≥170 | ≥30 | 85 - 110 |

| W70Cu3 | Approximately 650 - 750 | Approximately 550 - 650 | ≥10 | 180 - 220 |

| W75Cu2 | Approximately 700 - 800 | Approximately 600 - 700 | ≥8 | 200 - 240 |

| W80Cu2 | Approximately 750 - 850 | Approximately 650 - 750 | ≥6 | 220 - 260 |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.