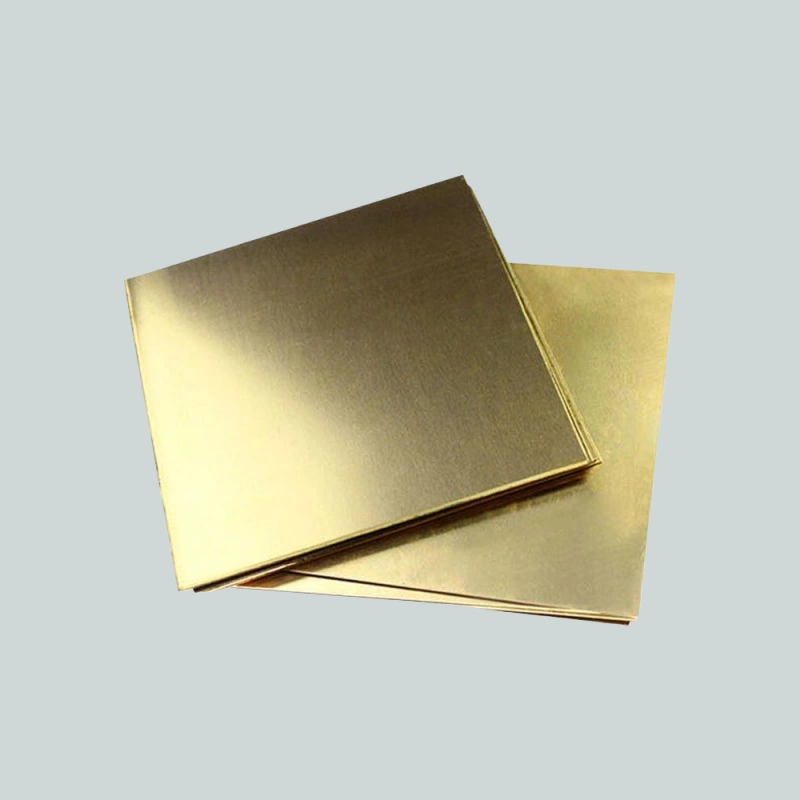

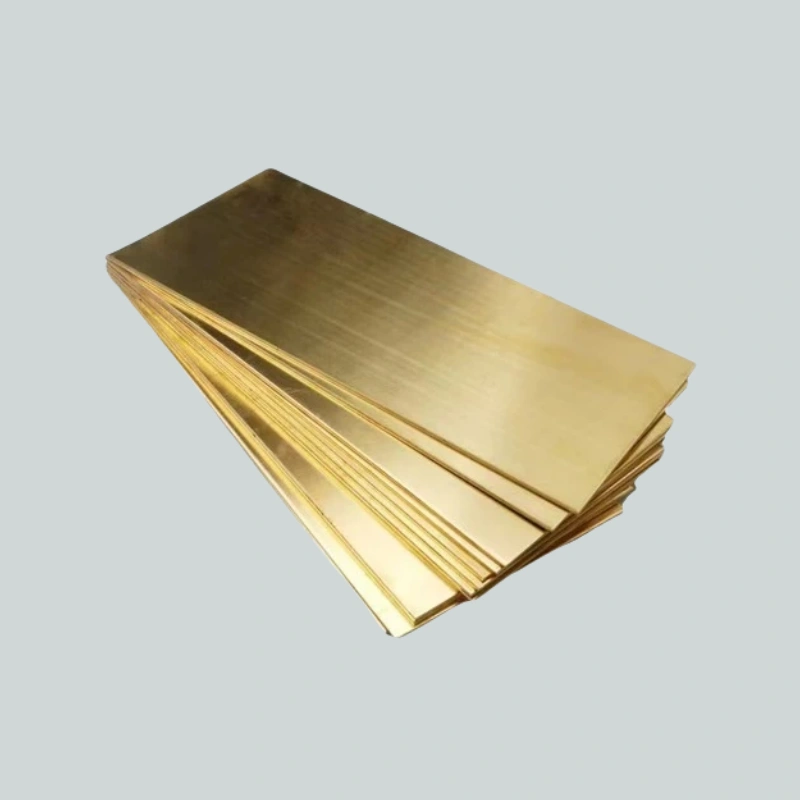

C27400/H63 Brass Plate

C27400 Yellow Brass is a high zinc content of brass alloy, its copper and zinc ratio of about 60% copper and 40% zinc, because of its excellent corrosion resistance, processing properties and beautiful appearance, often used in the manufacture of Marine applications, decorative accessories and high-performance hardware products.

Volume: 0