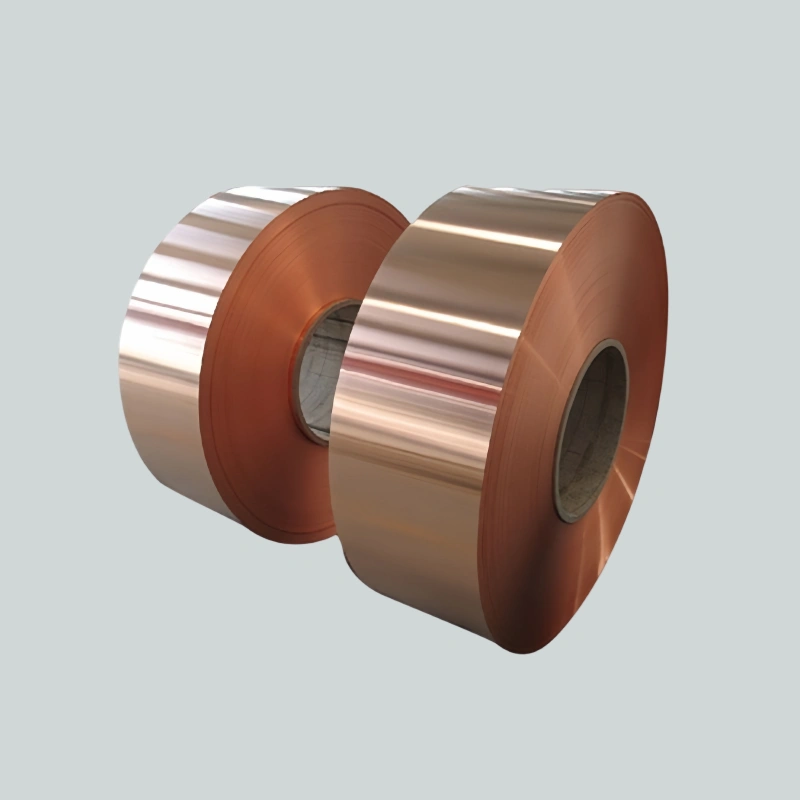

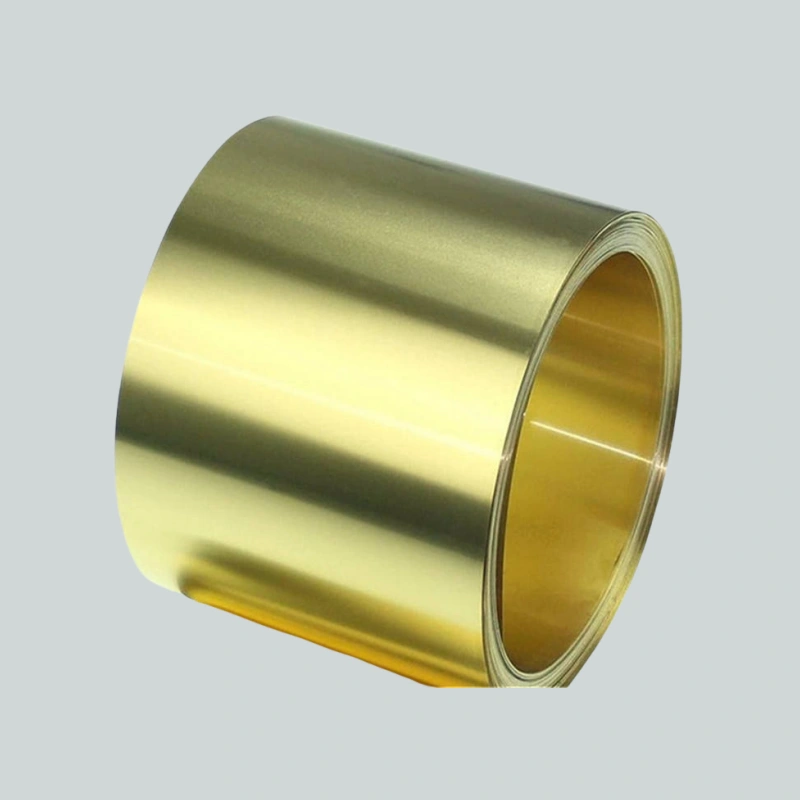

C91100 Tin Bronze: Premium High-Load Bearing Alloy

(SAE 65 | UNS C91100 | ASTM B271)

Cu 86-89% · Sn 11-13% · Zn ≤0.8% · Zero-Galling Champion · Steam Age Survivor

Product Overview: The Heavy-Duty Bearing Solution

For over a century, C91100 has been the backbone of industrial machinery requiring extreme pressure resistance. Developed for steam locomotives and modernized for tidal turbines, this centrifugal-cast bronze withstands 55 MPa bearing pressures at 4 m/s sliding speeds. Trusted by Siemens for hydroelectric shaft sleeves and Caterpillar for mining equipment bushings, it exceeds ASTM B271 Class 2 and MIL-B-17983D standards for critical marine, energy, and heavy industrial applications.

Technical Parameters

| Property | C91100 Value | C93200 Bronze | Gray Iron |

|---|

| Composition | Cu 86-89% | Cu 83% | Fe 95% |

| Sn 11-13% | Sn 7% | C 3% |

| Compressive Strength | 550 MPa | 450 MPa | 250 MPa |

| Bearing Pressure Limit | 55 MPa | 28 MPa | 15 MPa |

| Coefficient of Friction | 0.16 (lubricated) | 0.22 | 0.35 |

| Thermal Conductivity | 45 W/m·K | 40 W/m·K | 55 W/m·K |

| Cavitation Resistance | Grade A (ASTM G32) | Grade C | Grade D |

| Max Service Temp | 250°C (480°F) | 230°C | 425°C |

|

|

|

|

Certifications: ASTM B271 Class 2. EN 1982. MIL-B-17983D, Lloyds LR 2.4

Top 4 Competitive Advantages

Extreme Load Capacity

Handles 55 MPa bearing pressures (96% higher than C93200)

Self-Lubricating Microstructure

Tin-rich dendrites reduce friction by 35% in start-stop cycles

Saltwater Corrosion Immunity

0.002 mm/yr erosion in tidal zones (ASTM G50)

30-Year Lifespan Economy

3× longer service than aluminum bronze in stern tubes

Critical Performance Features

Anti-Galling Design: Eutectoid tin matrix prevents adhesive wear

Vibration Damping: 4× higher than steel (ASTM E756)

Embeddability: Absorbs 20μm abrasive contaminants

Thermal Shock Resistance: Withstands 150°C/minute gradients

Non-Sparking: ATEX/IECEx Zone 0 certified

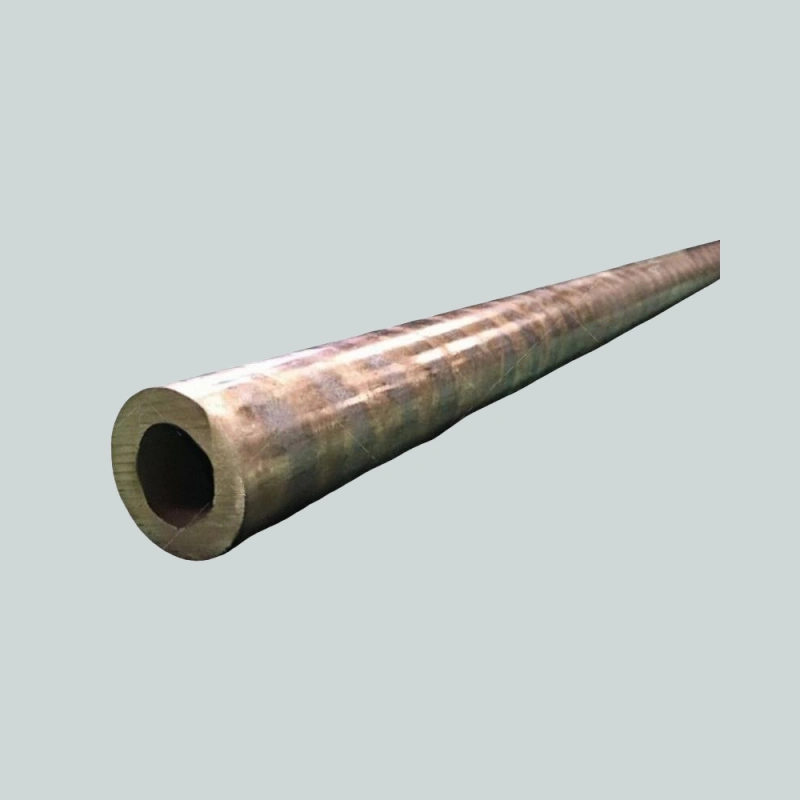

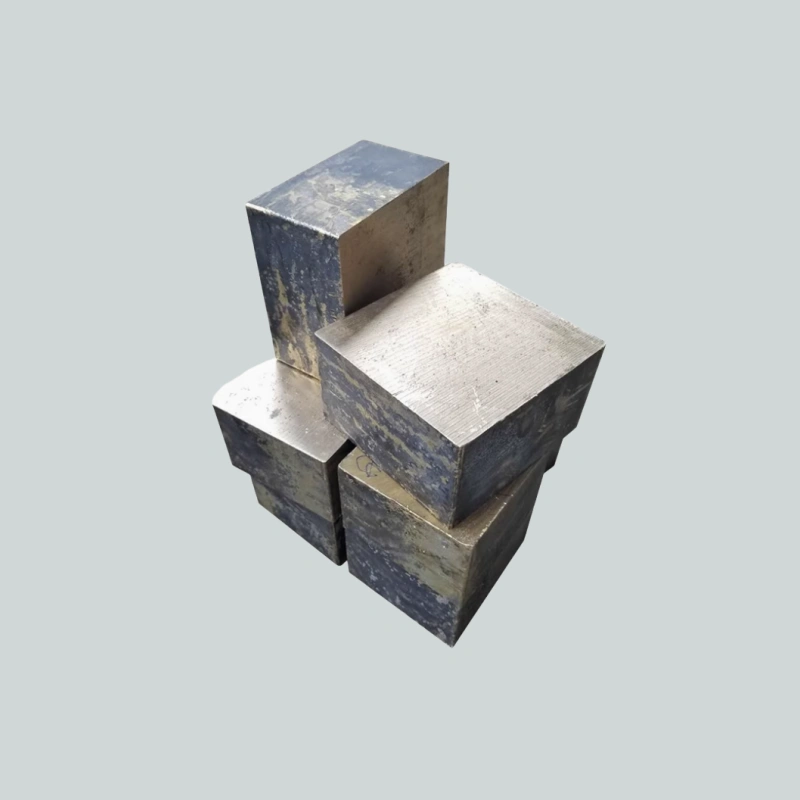

Precision Manufacturing Process

1 Vacuum Induction Melting

Oxygen-free Cu + Grade A Sn @ 1150°C under argon

2 Centrifugal Casting

700-900 RPM spin → zero-porosity structure

3 Controlled Solidification

Sand mold cooling @ 6°C/min → optimize δ-phase

4 Stress Relief

285°C × 5hr → dimensional stability

5 Quality Assurance

100% UT + radiography (ASTM E94) + Brinell testing

Core Applications

| Industry | Critical Components | Standards |

|---|

| Marine Engineering | Rudder bearings, propeller shafts | ABS 3. DNVGL-CP-0429 |

| Hydroelectric | Turbine guide bearings, wicket gates | IEC 60156. ASME PTC |

| Mining | Crusher eccentrics, dragline pins | MSHA 30 CFR 56/75 |

| Industrial | Steel mill rolls, crane sheaves | ISO 4378. ASTM A427 |

| Railway | Locomotive axle boxes, couplers | EN 12082. AAR M-126 |

Top Search Keywords:

C91100 bronze bushings | High-load bearing bronze | Marine shaft sleeves | Centrifugal cast C91100

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.