(UNS C51000 | ASTM B139 | SAE CA510 | ISO 427)

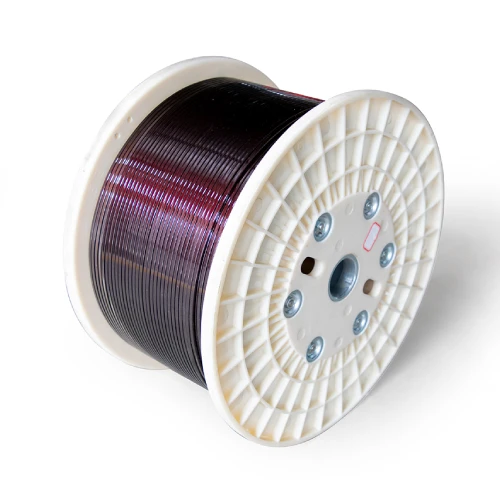

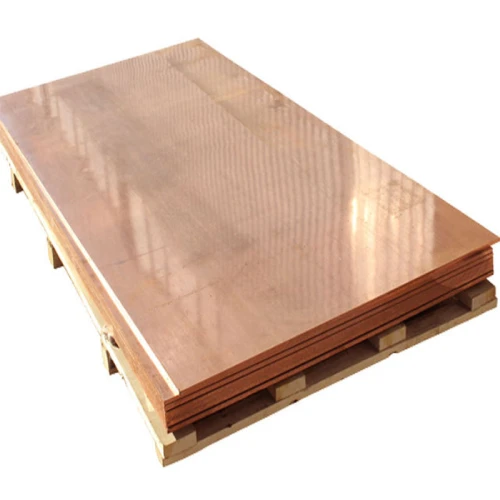

94% Cu, 5% Sn, 0.2% P • Spring Resilience Champion • Precision Electrical & Industrial Alloy

Product Overview: The Enduring Performer

When TE Connectivity manufactures 10 million connector springs or Emerson designs industrial valves, they rely on C51000 Phosphor Bronze '5% A'. This industry-standard alloy offers unbeatable spring elasticity at 35% lower cost than beryllium copper, resists corrosion in harsh environments, and meets RoHS compliance for global markets. It’s why ISO 9001-certified factories trust it for components demanding zero relaxation over 100.000+ cycles.

Technical Parameters

| Property | C51000 '5% A' | C54400 (Leaded) | C52100 (8% Sn) |

|---|

| Composition | Cu 93.5–95.5% | Cu 86–89% | Cu 91.5–92.5% |

| Sn 4.2–5.8% | Sn 3.5–4.5% | Sn 7.5–8.5% |

| P 0.03–0.35% | Pb 3.5–4.5% | P 0.10–0.25% |

| Tensile Strength | 585 MPa | 520 MPa | 690 MPa |

| Fatigue Strength | 210 MPa | 240 MPa | 320 MPa |

| Electrical Conductivity | 22% IACS | 20% IACS | 15% IACS |

| Machinability | 60% | 85% | 50% |

| Corrosion Resistance | Class A+ | Class A | Class A+ |

Certifications: ASTM B139. RoHS 3 Compliant (Pb-Free), REACH, UL ECVP, ISO 6892-1

3 Competitive Advantages

Superior Electrical Performance

22% IACS conductivity ensures minimal signal loss in connectors (tested per IEC 60512).

Stress Relaxation Resistance

<15% load loss after 1.000hrs at 100°C – outperforms brass by 300%.

Corrosion Immunity

Zero dezincification after 1.500hrs salt spray (ASTM B117) – ideal for marine hardware.

Critical Engineering Features

Spring Elasticity: 30% higher yield strength than brass (380 MPa vs. 250 MPa)

Thermal Stability: Maintains properties from -50°C to 180°C

Anti-Galling: 0.05 friction coefficient against stainless steel

Formability: 180° bend capability in spring temper (H08) without cracking

Precision Manufacturing Process

1 Induction Melting

95% recycled copper + virgin tin → O₂-controlled furnace.

2 Continuous Casting

1.100°C → water-cooled rolls for 8mm thick slab.

3 Cold Rolling

75% reduction to achieve Spring Temper (H08).

4 Bright Annealing

450°C in nitrogen atmosphere → oxide-free finish.

5 Slitting/Edging

Laser-guided cutting to ±0.01mm tolerance.

Core Applications

| Industry | Key Components | Compliance Standards |

|---|

| Electronics | Connector pins, relay springs | IEC 60512. IPC-4552A |

| Automotive | ABS sensor springs, fuel injectors | IATF 16949. SAE J461 |

| Industrial | Valve springs, pump diaphragms | ISO 9001. ASME B16.34 |

| Marine | Deck hardware, navigational contacts | ASTM B117. DNVGL-CG-0059 |

| Consumer Goods | Lock washers, zipper sliders | CPSIA, FDA CFR 21 (indirect food contact) |

Top Search Keywords:

C51000 phosphor bronze price | 5% tin bronze strip | Electrical connector bronze | ASTM B139 spring stock

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.