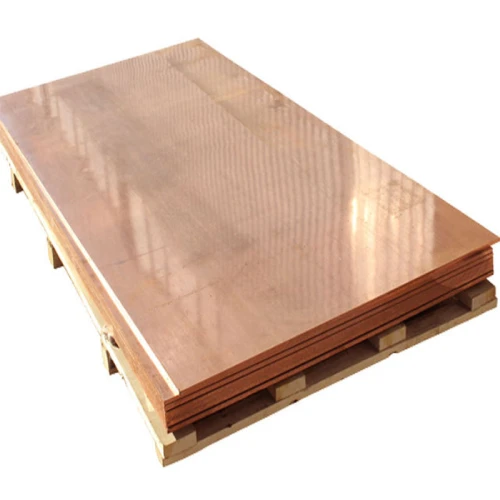

While lesser metals dissolve like sugar in seawater, CuNi 90/10 stands unshaken. This 90% copper-10% nickel alloy is the silent guardian of ships, offshore rigs, and desalination plants – laughing at salt spray, shrugging off barnacles, and outlasting vessels it protects.

TECH SPECS THAT DEFY THE SEA (UNS C70600 / DIN 2.0872)

| Property | CuNi 90/10 | Carbon Steel (For Context) |

|---|

| Composition | 88-90% Cu, 9-11% Ni, 1% Fe | 99% Fe |

| Corrosion Rate | 0.025 mm/year in seawater | 0.5-1.5 mm/year |

| Thermal Conductivity | 40 W/m·K | 45 W/m·K |

| Tensile Strength | 350-450 MPa | 370-480 MPa |

| Max Service Temp | 400°C | 350°C (prone to scaling) |

5 REASONS MARINE ENGINEERS SWEAR BY 90/10

Corrosion Assassin

“Survives 20+ years in tropical seawater without pitting – outperforms stainless steel 316L in splash zones. Salt? More like a mild seasoning.”

Biofouling Bodyguard

“Copper ions naturally repel mussels/algae. Save $500k/year per tanker on hull scraping dives.”

Chemical Warfare Veteran

“Takes sulfuric acid spills, ammonia bursts, and chlorine injections without flinching. Perfect for scrubber systems.”

Weldability Wizard

“No pre-heat needed, no post-weld cracks. Even your newest apprentice can join it flawlessly.”

Lifetime Cost Crusher

“Pay 3x upfront vs. steel → Save 12x on replacements over 25 years. CFOs call it ‘the annuity alloy’.”

HOW WE FORGE SEA IMMORTALITY

Step 1: Vacuum Induction Melting

“Raw metals fused in oxygen-free chambers – no impurities invited to this party.”

Step 2: Hot Extrusion

“Shaped at 900°C into seamless tubes/plates with grain structures tighter than submarine hatches.”

Step 3: Cold Pilger Rolling

“Wall thickness precision ±0.05mm – crucial for high-pressure seawater lines.”

Step 4: Solution Annealing

“Quenched to lock in corrosion-fighting microstructure. Think of it as metallurgical vaccination.”

WHERE IT RULES THE WAVES

| Industry | Critical Applications | Why 90/10 Wins? |

|---|

| Shipbuilding | Condenser tubes, hull sheathing | Slashes biofouling fuel costs 15% |

| Offshore Oil | Seawater cooling pipes, ballast systems | Zero crevice corrosion in welds |

| Desalination | Heat exchanger tubes, evaporator bodies | Handles brine 10x longer than titanium |

| Power Plants | Saltwater intake condensers | 30-year service life (vs. 8 for steel) |

| Aquaculture | Fish cage frames, water exchangers | Non-toxic to marine life |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.