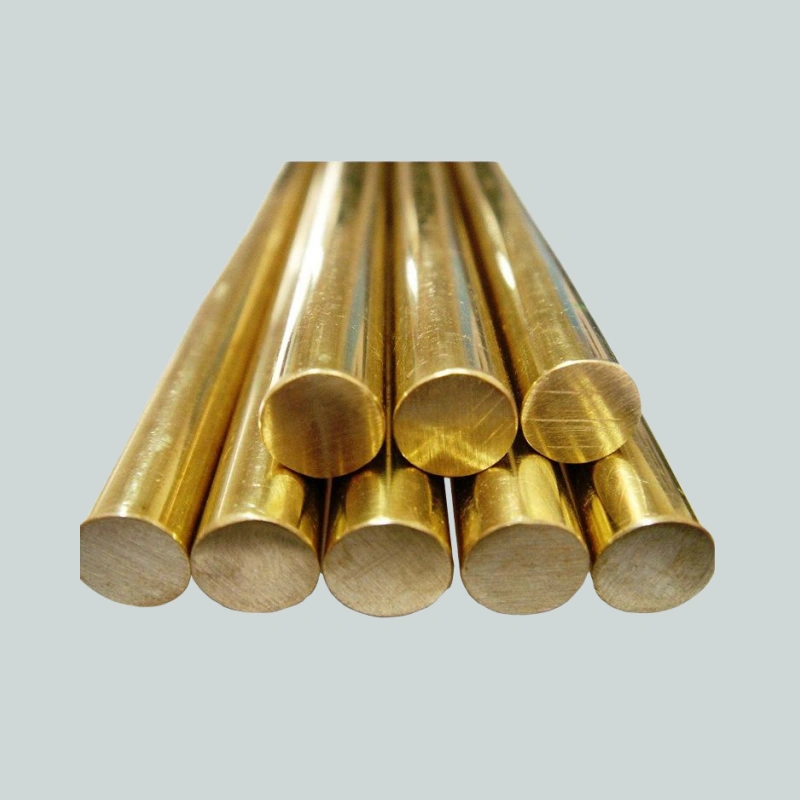

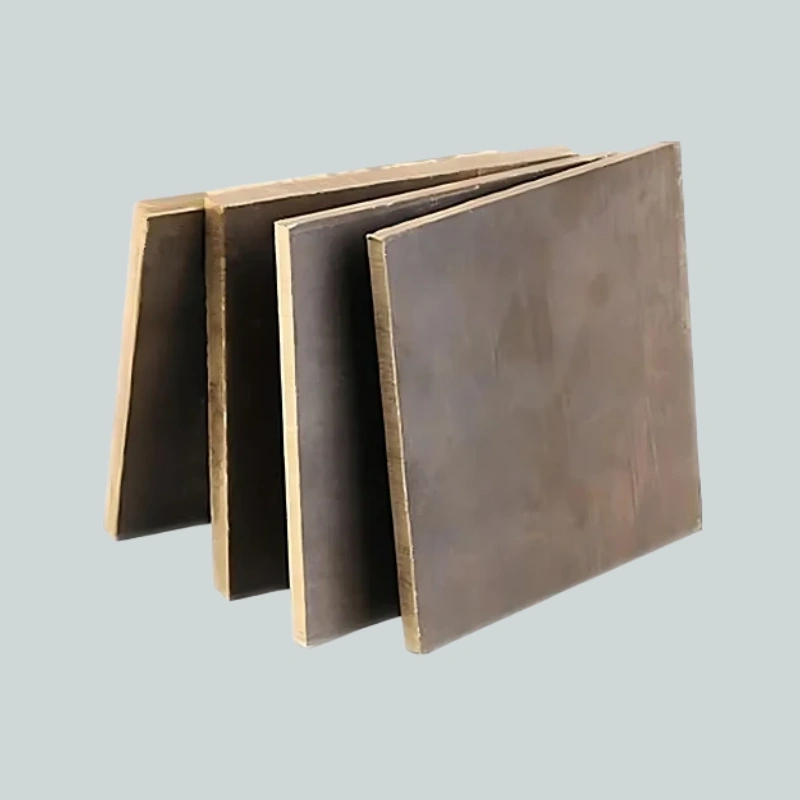

C90500 Tin Bronze "SAE 62": Marine-Grade Alloy for Demanding Environments

(ASTM B584 C90500 | SAE 62 | UNS C90500 | DIN G-CuSn10)

Cu 88-90% · Sn 9-11% · Zn ≤1.0% · Fe ≤0.1% · 225 MPa Yield Strength · Saltwater Champion

Product Overview: The Seawater Warrior

C90500 (SAE 62) is the gold standard for marine, pump, and valve components requiring unmatched corrosion resistance and reliability. With 60+ years of proven performance in naval and offshore applications, this high-tin bronze delivers 290 MPa tensile strength and 20% elongation – outperforming cheaper brass alloys in saltwater service. Certified to ASTM B584, EN 1982, and MIL-B-16578, it resists dezincification, cavitation, and biofouling even at 5-knot flow rates. Trusted by the U.S. Navy since 1968.

Technical Parameters

| Property | C90500 | C86300 Manganese Bronze | C95500 Ni-Al Bronze |

|---|

| Composition | Cu 89%, Sn 10%, Zn 1% | Cu 63%, Zn 25%, Mn 7% | Cu 81%, Al 11%, Ni 5% |

| Tensile Strength | 290 MPa | 725 MPa | 760 MPa |

| Corrosion Rate (Seawater) | 0.025 mm/yr | 0.18 mm/yr | 0.015 mm/yr |

| Impact Toughness | 55 J | 20 J | 35 J |

| Dezincification Resistance | Grade A | Grade D | Grade A |

| Max Operating Temp | 230°C | 260°C | 400°C |

|

|

|

|

Certifications: ASTM B584 Class C, ASME SB-584. DNVGL-CP-0091

Top 4 Competitive Advantages

Unrivaled Saltwater Performance

0.025 mm/yr corrosion rate (ASTM G48)

Superior Castability

Shrinkage <1.5% vs. aluminum bronze's 2.2%

Impact & Fatigue Resistance

55J Charpy impact strength at -20°C

30% Cost Savings

vs. nickel-aluminum bronze for equivalent marine parts

Critical Performance Features

Biofouling Resistance: 50% less barnacle adhesion vs. brass

Non-Sparking: Safe for hazardous marine environments

Pressure Integrity: Holds 6.900 kPa @ 150°C (ASME B16.34)

Machinability: 70% free-cutting rating (vs. 100% for C360 brass)

Erosion Resistance: Withstands 3% sand slurry flows

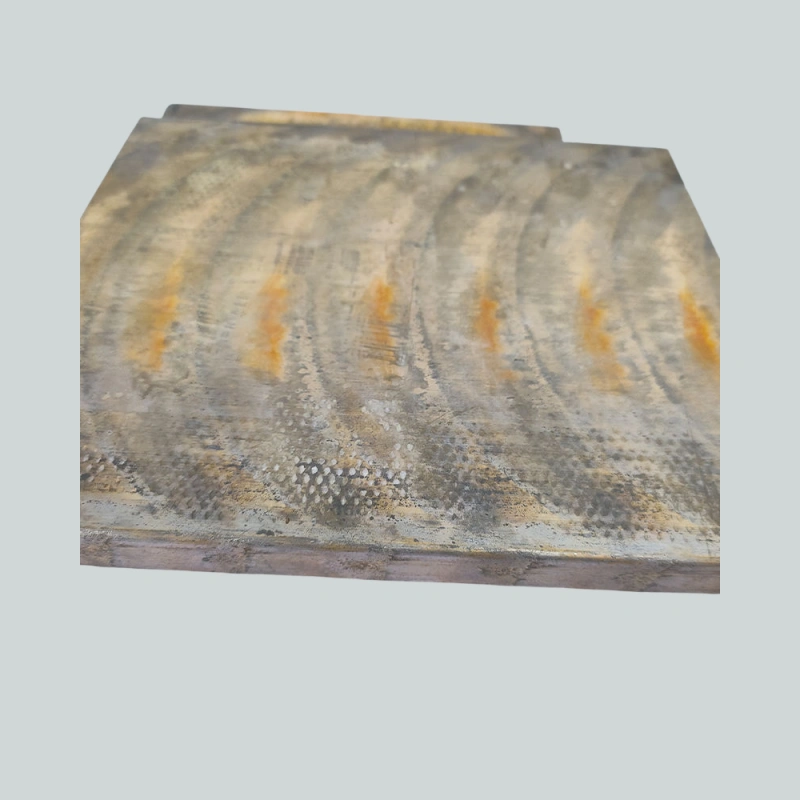

Manufacturing Process

1 Electric Arc Furnace Melting

Cu + Sn @ 1150°C → O₂ < 100 ppm

2 Sand Casting

Green sand molds → ASTM A247 Class II graphite structure

3 Solution Treatment

650°C × 8 hr → δ-phase homogenization

4 Stress Relieving

290°C × 2 hr → prevent seasonal cracking

5 Quality Validation

Radiographic testing per ASTM E94

Core Applications

| Industry | Critical Components | Standards |

|---|

| Marine & Offshore | Propellers, stern tubes, pump casings | ABS 3-9-7/8. Lloyds LR5 |

| Water Treatment | Valve trim, impellers, wear rings | AWWA C908. NSF/ANSI 61 |

| Power Generation | Turbine blades, condenser components | ASME PTC 19.5 |

| Mining | Sleeve bearings, slurry pump parts | ISO 4386-1 |

| Railway | Bushing blocks, brake system parts | AAR M-926 |

Top Search Keywords:

C90500 marine bronze | SAE 62 propeller alloy | Tin bronze pump parts | ASTM B584 castings

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.