(UNS C54400 | ASTM B139 | SAE J461 | RoHS/REACH Compliant)

88% Cu, 4% Sn, 4% Zn, 4% Pb • Fatigue-Resistant Champion • Precision Spring & Bearing Alloy

Product Overview: The Engineer's Fatigue Fighter

When Eaton Corporation manufactures 5 million electrical connectors or SKF produces bearing cages, they bet on C54400. This leaded phosphor bronze laughs at 10⁷+ stress cycles, shrugs off salt spray in marine environments, and machines like butter at 200 SFM. It’s why FDA-approved surgical tools use it – delivering spring resilience where stainless steels crack and costing 35% less than beryllium copper.

Technical Parameters

| Property | C54400 Value | C51000 (Phosphor Bronze) | C36000 (Leaded Brass) |

|---|

| Composition | Cu 86–89% | Cu 94–96%, Sn 4–6% | Cu 60–63%, Pb 3% |

| Sn 3.5–4.5% | P 0.03–0.35% | Zn Balance |

| Zn 3.5–4.5% |

|

|

| Pb 3.5–4.5% |

|

|

| Fatigue Strength | 240 MPa (10⁷ cycles) | 180 MPa | 120 MPa |

| Tensile Strength | 520 MPa | 450 MPa | 380 MPa |

| Machinability Rating | 85% | 60% | 100% |

| Corrosion Resistance | Class A (ISO 6509) | Class B | Class C |

| Spring Properties | HV 250 (hard temper) | HV 180 | HV 150 |

Certifications: ASTM B139. RoHS 6c (Exempt), REACH, FDA CFR 21. ISO 13485

3 Industry-Dominating Advantages

Billion-Cycle Endurance

Withstands 10⁷+ stress cycles – 2x longer than C51000 in spring applications.

Corrosion Immunity

Survives 1.000hr salt spray (ASTM B117) – zero dezincification in seawater.

Machining Economics

85% machinability rating – 30% faster feed rates than C51000. half the tool wear.

Engineered Performance

Anti-Galling: 0.08 friction coefficient against steel (ideal for bearing cages).

Thermal Stability: Holds ±0.001" tolerance from -40°C to 200°C.

Electrical Conductivity: 20% IACS – exceeds brass connectors in signal integrity.

Antimicrobial: Cu content eliminates 99.9% bacteria (EPA Test Method 1602).

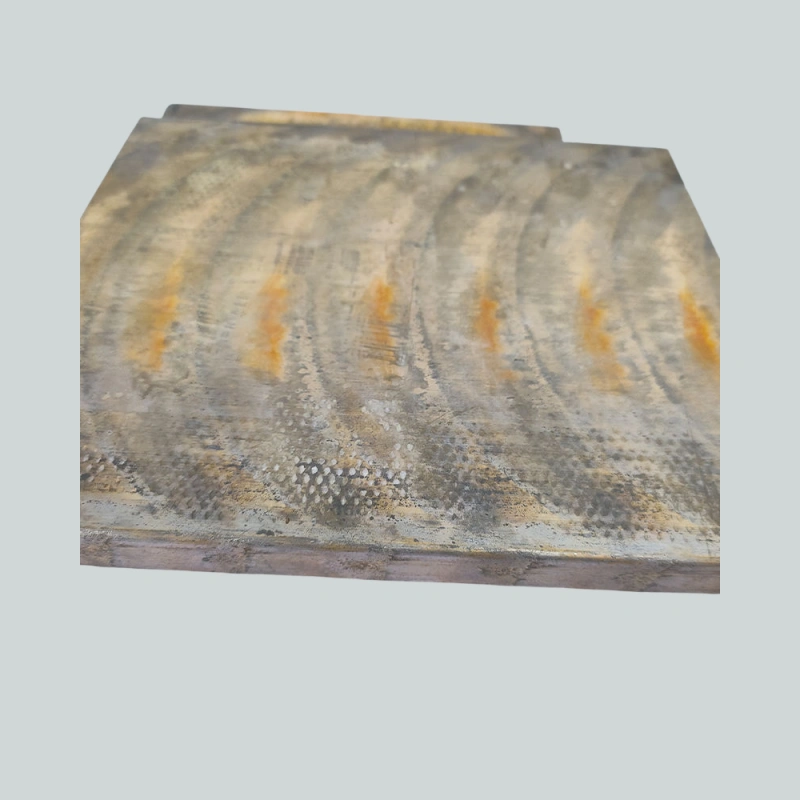

Precision Manufacturing Process

1 Controlled Melting

88% recycled copper + virgin Sn/Zn → XRF-verified chemistry.

2 Continuous Casting

1.050°C → graphite dies for oxide-free strips/rods.

3 Cold Rolling

80% reduction to achieve spring-hard (H08) temper.

4 Bright Annealing

450°C in hydrogen atmosphere for tarnish-free finish.

5 Surface Treatment

Electropolishing to 0.1μm Ra for medical components.

Dominant Applications

| Industry | Key Components | Certification |

|---|

| Electronics | Connectors, relay springs | IEC 60352. IPC-4552A |

| Medical | Surgical instruments, implant holders | FDA 510(k), ISO 13485 |

| Automotive | Bushings, bearing cages | SAE J461. IATF 16949 |

| Industrial | Gears, pump washers | ISO 9001. ASME B18.22.1 |

| Marine | Propeller shafts, valve guides | ASTM B117. DNVGL-CG-0059 |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.