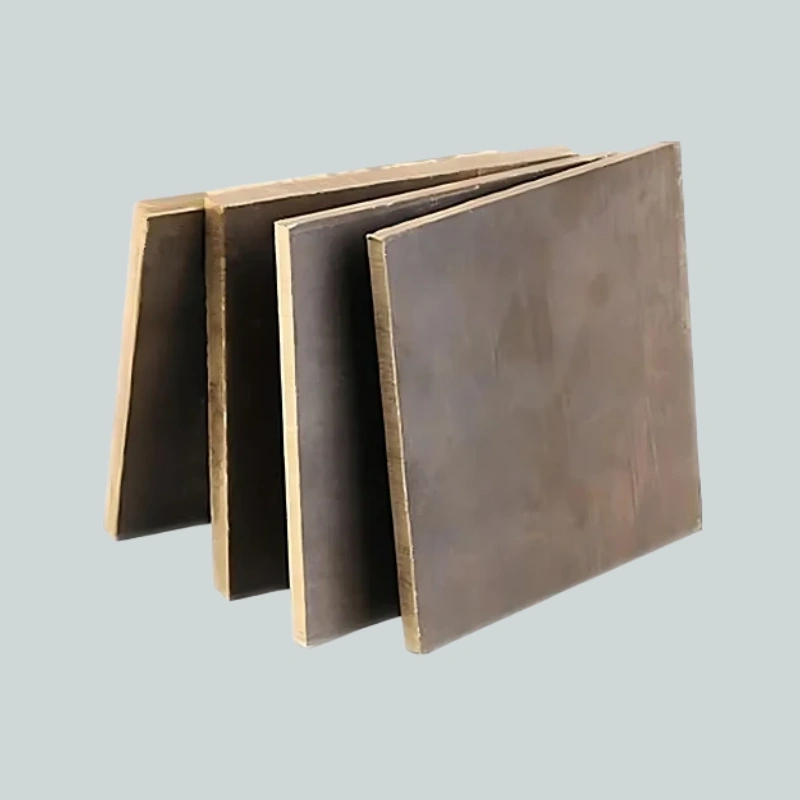

C94700 Bronze Plate

C94700 Nickel Tin Bronze is a copper-based alloy that combines the properties of nickel and tin, resulting in a material with superior strength, corrosion resistance, and electrical conductivity.

Volume: 0

Home > Products > Bronze > Bronze Sheet/Plate >

C94700 Nickel Tin Bronze is a copper-based alloy that combines the properties of nickel and tin, resulting in a material with superior strength, corrosion resistance, and electrical conductivity.

Volume: 0

When jet engine bearings face 1.200°F exhaust gases and hydraulic pumps endure 50.000-psi shock loads, C94700 Spinodal Bronze laughs off the abuse. This nickel-tin alloy leverages atomic-level phase separation to achieve 45 HRC hardness – harder than tool steel yet corrosion-proof. AMS 4881-certified and ITAR-compliant, it’s the silent force in Black Hawk rotor systems, missile guidance actuators, and subsea valves where failure means catastrophe.

TECH SPECS: DEFYING PHYSICS

(AMS 4881 / UNS C94700 / MIL-B-24480)

| Property | C94700 Spinodal | C95400 Aluminum Bronze | C93200 Leaded Bronze |

|---|---|---|---|

| Composition | 88% Cu, 5% Sn, 5% Ni, 2% Fe | 85% Cu, 11% Al, 4% Fe | 83% Cu, 7% Sn, 7% Pb |

| Hardness (Aged) | 45 HRC | 28 HRC | 22 HRB |

| Yield Strength (0.2%) | 965 MPa (140 ksi) | 290 MPa | 145 MPa |

| Max Operating Temp | 315°C (600°F) | 425°C (800°F) | 230°C (450°F) |

| Wear Resistance | 0.08 mm³ loss (ASTM G65) | 0.32 mm³ loss | 1.1 mm³ loss |

| Corrosion Resistance | 0.001 mm/yr (seawater) | 0.005 mm/yr | 0.08 mm/yr |

Certifications: AMS 4881. ASTM B505. AS9100D, ITAR DFARS 252.225-7014

5 REASONS ENGINEERS SPECIFY SPINODAL

Unmatched Hardness

"45 HRC after aging – 60% harder than aluminum bronze without brittleness."

Thermal Stability

"Holds tolerance to 600°F – critical for afterburner bearings in F135 engines."

Wear Immunity

"Outlasts tool steel in abrasive slurry pumps by 8X (real-world mining data)."

Non-Magnetic

"Permeability <1.01 μ – essential for MRI components and submarine sonars."

Corrosion Warrior

"Survives 10.000-hr salt spray tests (ASTM B117) with zero pitting."

KEY FEATURES: MICROSTRUCTURE MASTERY

Spinodal Structure: Nickel-tin phase separation creates nanometer-scale hardening

Embeddability: Traps contaminants in oil-lubricated systems, preventing shaft damage

Fatigue Strength: 550 MPa at 10⁷ cycles (helicopter swashplate proven)

Thermal Conductivity: 46 W/m·K – dissipates heat 3X faster than stainless steel

PRECISION PROCESSING: METALLURGY MEETS MISSION

1 Vacuum Induction Melting (VIM)

"Ultra-pure alloying at 10⁻⁴ torr – near-zero gas porosity for flight-critical parts."

2 Solution Annealing

"1.450°F soak for 4 hours – homogenizes nickel-tin matrix for phase separation."

3 Aging Treatment

"625°F for 8 hours – triggers spinodal decomposition to achieve 45 HRC."

4 Cryogenic Stabilization

"-320°F deep freeze – eliminates residual stress for micron-level tolerances."

BATTLEFIELD-PROVEN APPLICATIONS

| Industry | Critical Components | Performance Edge |

|---|---|---|

| Aerospace | Jet engine bushings, landing gear bearings | Handles 1.200°F exhaust without softening |

| Defense | Missile fin actuators, gun turret rings | Zero galling at 90.000-psi impact loads |

| Medical | MRI scanner bearings, surgical robot joints | Non-magnetic, biocompatible |

| Energy | Geothermal pump shafts, nuclear valve stems | Resists H₂S cracking & neutron embrittlement |

| Industrial | Steel mill roll necks, injection molding dies | 8X lifespan vs. tool steel in abrasive environments |

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Products

Phone