Product parameters

Size range

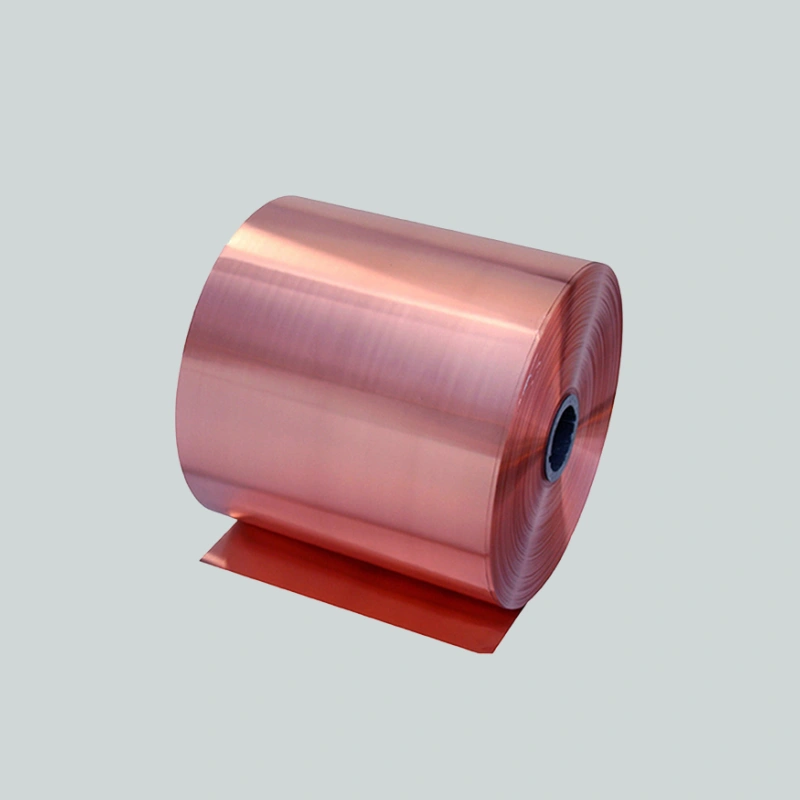

Strip:

Thickness: 0.05–3.0mm (common 0.05–0.8mm), can be as thin as 0.01mm for special customization.

Width: Standard width is 200mm, but can be customized to 10–1000mm in strip width.

Coil: Supplied in rolls, thickness range is the same as strip, width is slit as required.

International Standards

The manufacture and application of C17200 beryllium copper follows a number of international standards:

ASTM Standards:

ASTM B196/B196M: Standardizes the chemical composition, mechanical properties, etc. of bars and strips.

ASTM B194: Applicable to plates, sheets, strips and rolled bars, covering C17000 and C17200 alloys.

Other Standards:

UNS Number: C17200 is a typical beryllium copper alloy in the United States Unified Numbering System (UNS).

ISO/ROHS Certification: The product has passed ISO quality system and ROHS environmental certification.

AMS 4533: Aerospace material standard for high-strength beryllium copper alloys.

Chemical composition (weight percentage)

Core elements:

Beryllium (Be): 1.80-2.15%

Cobalt (Co): 0.35-0.65%, or ≥0.20% when combined with nickel.

Nickel (Ni): 0.20-0.25%, or ≤0.6% when combined with cobalt.

Copper (Cu): Remainder, usually ≥99.5%.

Impurity limits:

Silicon (Si), iron (Fe), aluminum (Al) are all ≤0.15%.

Titanium (Ti): 0.10-0.25%

Mechanical Properties

The performance indicators are significantly affected by the heat treatment state, mainly divided into age-hardened state and annealed state:

Age-hardened state (high-strength state):

Tensile strength: 1105-1520 MPa, up to 1520 MPa (220 ksi).

Yield strength (0.2% offset): 1035-1345 MPa.

Hardness: 38-44 HRC, up to HRC 45 after peak aging.

Elongation: 1-2%, low elongation is associated with high strength.

Annealed or soft state:

Tensile strength: 590-830 MPa.

Elongation: up to 24%.

Other key properties:

Elastic modulus: 128-185 GPa, different literatures have different values due to different test methods.

Fatigue limit: equivalent to special steel, with high fatigue resistance.

Impact toughness: at least 32 J.

Physical properties

Density: 8.25-8.36 g/cm³.

Thermal conductivity: 105 W/(m·K) (20℃), some literature gives higher values (324 W/(m·℃), the unit or test conditions may be different).

Electrical conductivity: 18-22% IACS, high conductivity is one of its core advantages.

Thermal expansion coefficient: 17-24.3×10⁻⁶/℃.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.