Product Parameters

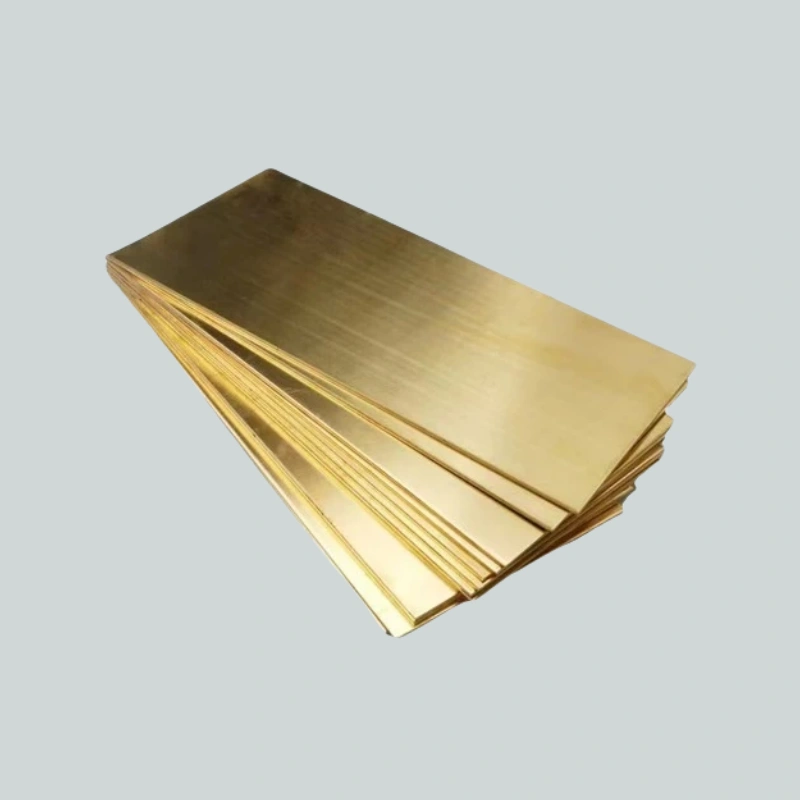

Conductor Material: 99.95% pure copper (ETP grade) or 99.7% aluminum (1060/1350 series)

Dimensions:

Width: 2.0mm – 25.0mm

Thickness: 0.5mm – 8.0mm

Paper Wrapping Layers: 2 – 8 layers (each layer 0.05mm – 0.12mm thick)

Insulation Class: Class 105 (A), Class 130 (B) (kraft cable paper with impregnated options for higher temps)

Tensile Strength: Copper core ≥ 205 MPa; Aluminum core ≥ 90 MPa

Elongation: ≥ 15% (copper); ≥ 12% (aluminum)

Breakdown Voltage: ≥ 5kV (2 layers); ≥ 15kV (8 layers) (varies with layer count and impregnation)

Standards Compliance: IEC 60554. NEMA MW 1000. GB/T 13035

Product Advantages

Superior Dielectric Performance: Cable paper insulation provides excellent voltage resistance, ideal for high-voltage transformers and reactors where insulation reliability is critical.

Space Efficiency: Flat shape allows 25-30% higher packing density than round wire, reducing the size of electrical equipment.

Cost-Effective Insulation: Paper wrapping is more affordable than enamel or plastic insulation for large-diameter conductors, lowering material costs by 15-20%.

Impregnation Compatibility: Works well with insulating oils and resins, enhancing moisture resistance and dielectric strength when fully impregnated.

Material Flexibility: Choose copper for maximum conductivity (98% IACS) or aluminum for weight savings (30% lighter) in non-critical applications.

Product Features

Uniform Wrapping: Tightly wrapped cable paper with consistent overlap (15-20%) ensures no gaps in insulation, preventing voltage breakdown.

Smooth Edges: Flat conductor has rounded edges (radius ≥ 0.2mm) to prevent paper tearing during wrapping and handling.

Oil Absorption: Unimpregnated paper readily absorbs insulating oil, forming a solid dielectric barrier when used in oil-immersed equipment.

Mechanical Protection: Paper layers cushion the conductor against minor impacts and abrasion during installation.

Environmentally Friendly: Cable paper is biodegradable and recyclable, making it a more sustainable choice than synthetic insulations.

Product Process

Conductor Forming: Copper/aluminum rods are rolled into flat strips, then annealed to achieve the desired ductility.

Surface Cleaning: The flat conductor is degreased and dried to ensure proper adhesion with wrapping paper.

Cable Paper Wrapping: Automated machines wrap cable paper around the flat conductor with precise tension and overlap, ensuring uniform coverage.

Drying: Wrapped wire is dried at 80-100°C to remove moisture from the paper, preventing insulation degradation.

Impregnation (Optional): For enhanced performance, wire is impregnated with insulating oil or resin, then cured to seal the paper.

Quality Testing: Includes breakdown voltage testing, wrapping tightness checks, and conductor dimension verification.

Main Application Fields

Power Transformers: Core and winding conductors in distribution and power transformers, especially oil-immersed types.

Reactors: Current-limiting reactors and shunt reactors where high dielectric strength is required.

Electrical Motors: Large industrial motors with high voltage ratings, using paper-wrapped wire for reliable insulation.

Generators: Stator and rotor windings in small to medium-sized generators.

Distribution Equipment: Bus bars and conductors in switchgear and distribution panels where space is limited.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.