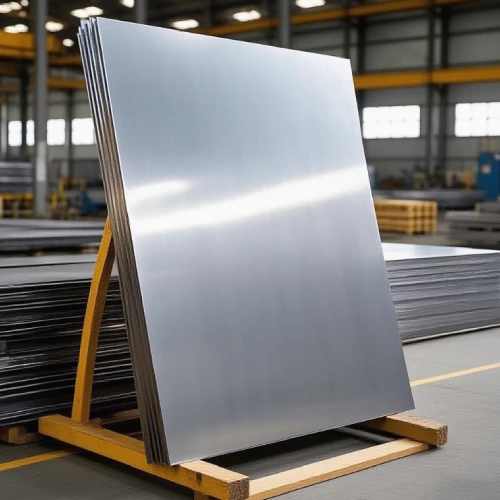

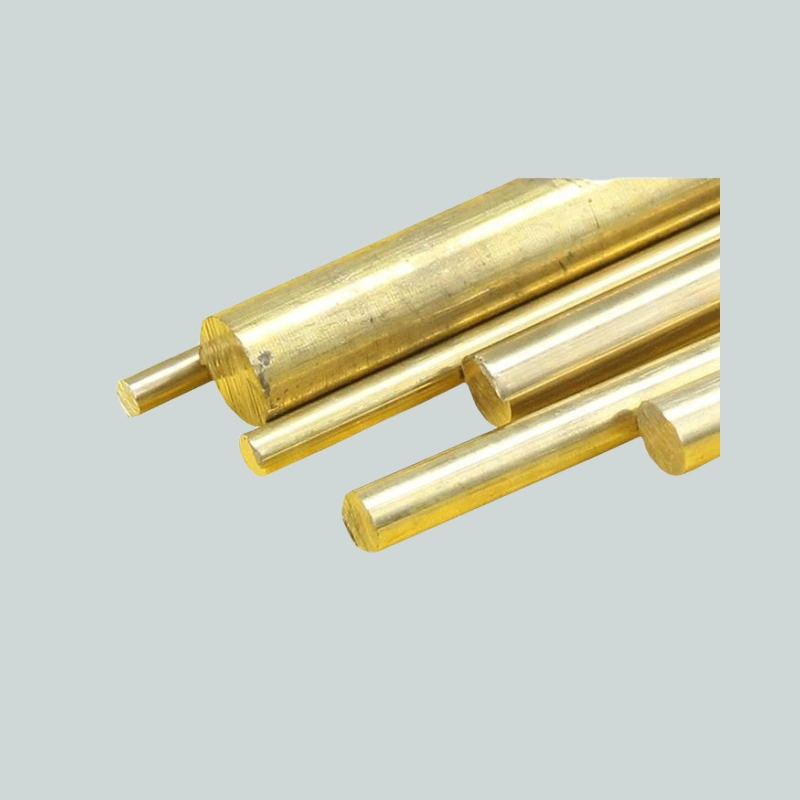

Product Parameters

Composition: Cu 70%, Ni 30%, with additions of iron and manganese

Thickness: 2-50mm

Width: Up to 2500mm

Length: Up to 12000mm

Temper: Soft (O), half-hard (1/2H), hard (H)

Surface Finish: Mill finish, polished, or as specified

Compliance: ASTM B122. ASME SB122. EN 12164

Product Advantages

Superior Corrosion Resistance: Withstands seawater, brackish water, and chemical exposure, reducing maintenance costs.

Thermal Conductivity: Efficient heat transfer for heat exchangers and condensers.

Anti-Fouling: Naturally resists biofouling without toxic coatings.

High Strength: Maintains structural integrity under stress and temperature fluctuations.

Weldability: Easily joined using conventional methods, ensuring seamless fabrication.

Product Features

Low Magnetic Permeability: Ideal for electronic and naval applications.

Manganese Addition: Enhances mechanical properties and resistance to impingement corrosion.

Formability: Suited for complex shaping without cracking.

Longevity: Designed for extended service life in demanding environments.

Product Process

Our CuNi 70/30 plates are manufactured via:

Vacuum Melting: Ensures purity and homogeneity.

Hot Rolling: Precision-controlled to achieve desired thickness and grain structure.

Cold Rolling & Annealing: Refines mechanical properties and surface finish.

NDT Testing: Ultrasonic and eddy current inspections guarantee defect-free material.

Main Application Fields

Marine Engineering: Ship hulls, seawater piping, condensers.

Desalination Plants: Heat exchangers and brine handling systems.

Oil & Gas: Offshore platforms, subsea equipment.

Power Generation: Nuclear and thermal power plant components.

Chemical Processing: Reactors and storage tanks.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.