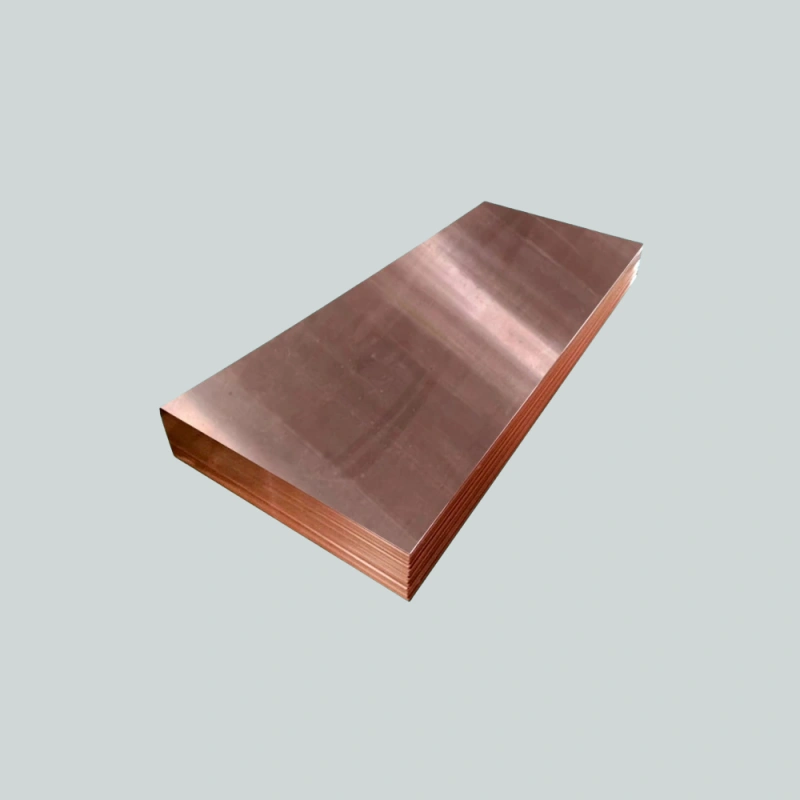

Product Parameters

Conductor Material: 99.95% pure copper (ETP grade) or 99.7% aluminum (1060/1350 series)

Dimensions:

Width: 2.0mm – 30.0mm

Thickness: 0.6mm – 10.0mm

Polyester Film Thickness: 0.02mm – 0.05mm (1 – 2 layers)

Non-woven Fabric Thickness: 0.05mm – 0.1mm (1 – 2 layers)

Insulation Class: Class 155 (F) (continuous operating temperature up to 155°C)

Tensile Strength: Copper core ≥ 210 MPa; Aluminum core ≥ 95 MPa

Elongation: ≥ 16% (copper); ≥ 13% (aluminum)

Breakdown Voltage: ≥ 6kV (single film + single fabric); ≥ 12kV (double film + double fabric)

Standards Compliance: IEC 60317-42. NEMA MW 1000. GB/T 6109.21

Product Advantages

Dual Insulation Protection: Polyester film provides excellent dielectric strength, while non-woven fabric adds mechanical toughness—resisting cuts and abrasion 30% better than single-layer insulation.

Space Efficiency: Rectangular profile allows 25-35% higher packing density than round wire, reducing equipment size in transformers and motors.

Moisture Resistance: Polyester film acts as a barrier to moisture, while non-woven fabric absorbs minimal water (< 5% by weight), maintaining performance in humid environments.

Cost-Effective Performance: Balances high insulation quality with moderate material costs, offering 20% savings over fully film-insulated wire without sacrificing reliability.

Material Versatility: Copper (98% IACS conductivity) suits high-efficiency applications; aluminum (62% IACS) cuts weight by 30% for less demanding uses.

Product Features

Secure Bonding: Polyester film is heat-laminated to the conductor, while non-woven fabric is tightly wrapped with 10-15% overlap, preventing delamination.

Rounded Corners: Conductor edges (radius ≥ 0.2mm) protect insulation from punctures during bending and winding.

Flexible Handling: Easily formed into complex shapes (minimum bend radius: 3× thickness for copper, 4× for aluminum) without insulation cracking.

Chemical Compatibility: Resists mineral oils, mild acids, and industrial cleaning agents common in manufacturing settings.

Uniform Insulation: Automated wrapping ensures consistent layer thickness (±0.003mm), guaranteeing predictable dielectric performance.

Product Process

Conductor Rolling: Copper/aluminum rods are rolled into rectangular strips, annealed to optimize ductility for wrapping.

Surface Preparation: Ultrasonic cleaning removes oxides and contaminants, ensuring strong adhesion with polyester film.

Polyester Film Lamination: Film is applied via hot rolling (120-150°C) to bond directly to the conductor, forming a smooth base layer.

Non-woven Fabric Wrapping: Automated machines wrap fabric around the film-laminated conductor with controlled tension to avoid wrinkles.

Curing: Final heat treatment (80-100°C) sets the wrapping, enhancing adhesion between layers.

Quality Validation: Includes breakdown voltage testing, insulation thickness checks, and bend tests to verify flexibility.

Main Application Fields

Industrial Transformers: Medium-voltage transformers in manufacturing plants, where dual insulation withstands thermal cycling.

Motors & Generators: Large AC motors and synchronous generators, using rectangular shape for efficient winding.

Renewable Energy Systems: Inverters and power conditioning units in wind and solar installations, resisting outdoor moisture.

Railway Equipment: Traction motors and control transformers, where mechanical durability handles vibration.

Marine Electricals: Shipboard motors and transformers, leveraging moisture resistance in humid, salt-air environments.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.