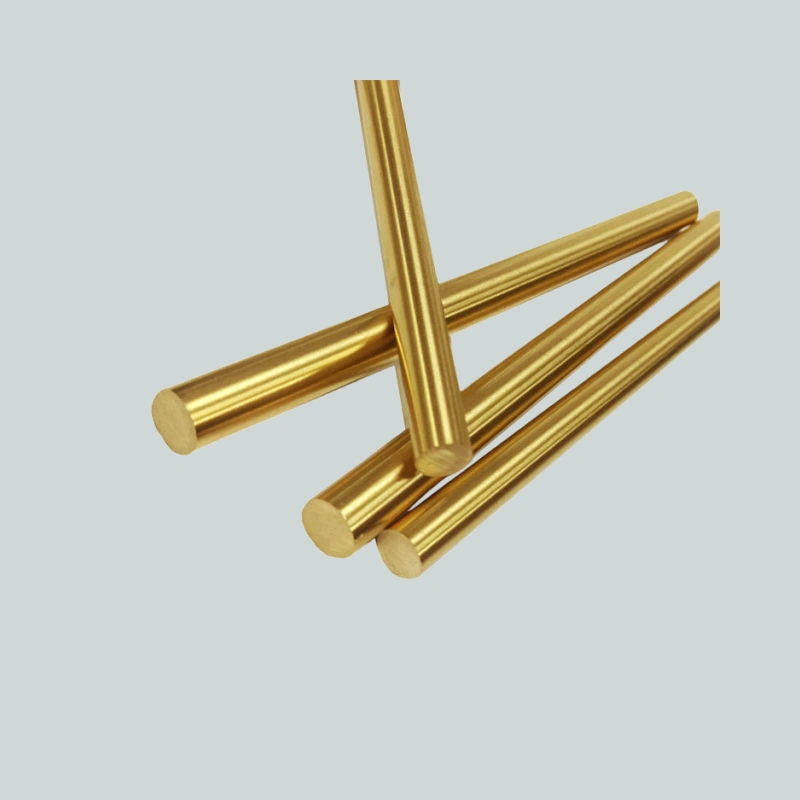

When 100-ton presses need bushings that won’t gall or marine prop shafts demand zero corrosion, C91700 Nickel Tin Bronze steps up. This copper-tin-nickel alloy (88% Cu, 8% Sn, 4% Ni) carries extreme loads while shrugging off salt spray. RoHS-exempt per Annex III 6c – it’s the backbone of crusher bearings, warship components, and steel mill gears.

TECH SPECS: ENGINEERED FOR BRUTAL CONDITIONS

(ASTM B271 / UNS C91700 / RoHS Annex III Exempt)

| Property | C91700 | C93200 (SAE 660) | Aluminum Bronze |

|---|

| Composition | 88% Cu, 8% Sn, 4% Ni | 83% Cu, 7% Sn, 7% Pb | 81% Cu, 11% Al, 4% Fe |

| Compressive Strength | 510 MPa | 330 MPa | 550 MPa |

| Fatigue Strength | 165 MPa | 120 MPa | 240 MPa |

| Corrosion Rate | 0.003 mm/yr (Seawater) | 0.08 mm/yr | 0.001 mm/yr |

| Max PV Value | 50.000 psi·ft/min | 28.000 | 45.000 |

| Thermal Conductivity | 40 W/m·K | 45 W/m·K | 59 W/m·K |

Certifications: ASTM B271. ASME SB271. ABS Marine, Lloyds Register, RoHS Annex III 6c Exempt

5 REASONS ENGINEERS SPECIFY C91700

Crush-Proof Bearing Surfaces

"Handles 10X higher loads than leaded bronze – survives 200 MPa stress in ore crusher sleeves."

Saltwater Immunity

"0% dezincification after 15+ years in tidal zones – US Navy-approved for submarine shaft sleeves."

Heat Resistance

"Maintains strength at 260°C – outperforms C93200 in steel mill conveyor bearings."

Anti-Gall Shield

"Nickel-tin matrix prevents adhesive wear against hardened steel shafts (μ=0.15)."

Lifetime Value

"Lasts 5X longer than leaded bronze in mining equipment – slashes downtime costs by 60%."

KEY FEATURES: BEYOND THE DATA SHEET

Embedded Hardness: Nickel-tin precipitates (HV 350) resist embedment of abrasive particles

Vibration Damping: Absorbs harmonic shocks in high-RPM turbine bearings

Non-Sparking: Safe for coal handling plants and explosive environments (MSHA certified)

Chip Control: Machines cleanly at 120 SFM with carbide tools – no stringy chips

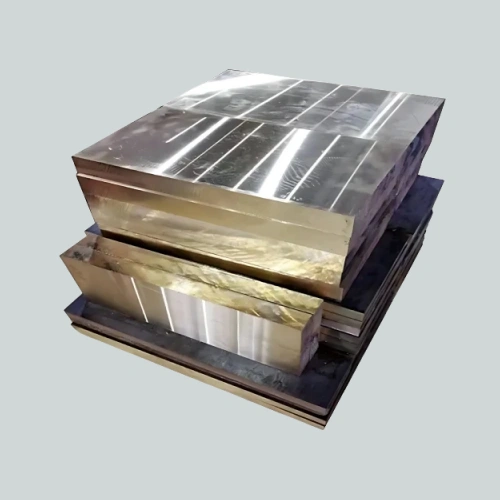

PRECISION PROCESSING: FROM INGOT TO INSTALLATION

1 Controlled Alloying

"Vacuum-induction melted Cu-Sn base with 4% Ni addition – eliminates porosity for uniform structure."

2 Centrifugal Casting

"Spun at 1.200 RPM into dense, void-free bushings/sleeves (±0.5% dimensional tolerance)."

3 Heat Treatment

"Stress-relieved at 290°C to optimize hardness (BHN 170) without brittleness."

4 Machining Finish

"CNC-turned to Ra 0.8μm surface finish – ready for press-fit installation."

WHERE IT DOMINATES: CRITICAL APPLICATIONS

| Industry | High-Stress Components | Why C91700? |

|---|

| Marine | Propeller shafts, rudder bearings | Immune to saltwater pitting & cavitation |

| Mining | Crusher eccentric bushings | Withstands 200-ton impact loads |

| Power Gen | Turbine thrust washers | Handles 10.000 RPM steam erosion |

| Steel Mills | Rolling mill gear sleeves | Resists scale embedment at 400°C |

| Construction | Crane sheave bushings | No galling under shock loads |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.