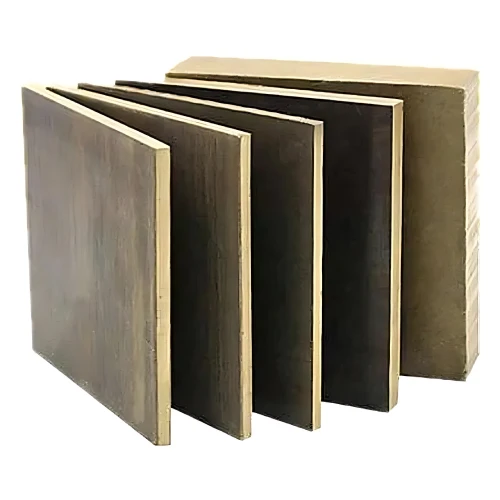

ASTM C51900 Phosphor Bronze

C51900 Phosphor Bronze is valued for its electrical and thermal conductivity, mechanical properties, and corrosion resistance, making it an important alloy in many industries where these qualities are essential.

Volume: 0

Home > Products > Bronze > Bronze Sheet/Plate >

C51900 Phosphor Bronze is valued for its electrical and thermal conductivity, mechanical properties, and corrosion resistance, making it an important alloy in many industries where these qualities are essential.

Volume: 0

When fatigue life is non-negotiable and electrical contacts must outlive the machine, ASTM C51900 Phosphor Bronze delivers. This tin-phosphorus bronze (6% Sn, 0.15% P) bends, flexes, and conducts decade after decade. From aerospace relays to guitar frets – it’s the alloy that won’t quit.

TECH SPECS: ENGINEERED FOR ENDURANCE

(ASTM B139 / UNS C51900 / RoHS/REACH Compliant)

| Property | C51900 Bronze | C51000 (5% Sn) | Beryllium Copper |

|---|---|---|---|

| Composition | 94% Cu, 6% Sn, 0.15% P | 95% Cu, 5% Sn | 98% Cu, 2% Be |

| Tensile Strength | 690 MPa | 550 MPa | 1.300 MPa |

| Fatigue Strength | 320 MPa (10⁷ cycles) | 280 MPa | 480 MPa |

| Conductivity (IACS) | 15% | 18% | 22% |

| Spring Properties | Elastic Limit: 85% | 75% | 90% |

| Corrosion Resistance | 5 star (Seawater) | 4 star | 5 star |

Certifications: ASTM B139. SAE J461. RoHS 3. REACH, DFARS

5 REASONS INDUSTRY RELIES ON C51900

Infinite Flex Life

“Endures 50M+ compression cycles in fuel injector springs – 2X the lifespan of cheaper bronzes.”

Electrical Integrity

“Maintains stable contact resistance (<2mΩ) after 100K mating cycles – critical for EV battery disconnects.”

Corrosion Fighter

“Survives 1.000hr salt spray (ASTM B117) – ideal for marine instrument springs.”

Machinability Master

“Chips cleanly at 150 SFM with carbide tools – 30% faster than beryllium copper.”

Cost-Smart Performance

“Delivers 90% of beryllium copper’s spring performance at 60% lower cost.”

UNIQUE FEATURES: BEYOND THE DATA SHEET

Stress Relaxation Resistance: Loses just 15% load after 1.000hrs at 150°C (vs. 35% for brass)

Weldability: Seamless TIG welding without embrittlement – perfect for custom sensor housings

Anti-Galling Properties: Phosphide inclusions prevent adhesive wear in threaded inserts

Thermal Stability: Coefficient of expansion matches steel – no fretting in thermal-cycling environments

PRECISION PROCESSING: HOW WE MAKE IT

1 Controlled Alloying

"Vacuum-melted 94/6 Cu-Sn blend with 0.15% P – eliminates porosity for uniform grain structure."

2 Continuous Casting

"Extruded at 700°C into rods/strips with ±0.03mm dimensional tolerance."

3 Cold Rolling

"Hardened to H04 temper (Rockwell B 98) for spring applications via 80% reduction."

4 Quality Verification

"Every coil eddy-current tested; batch-specific certs include fatigue test reports."

WHERE IT EXCELS: INDUSTRY APPLICATIONS

| Industry | Critical Components | Why C51900? |

|---|---|---|

| Aerospace | Relay contacts, bearing cages | Zero spark risk in oxygen-rich environments |

| Automotive | ABS sensor springs, shift forks | Withstands -40°C to 150°C thermal cycling |

| Electronics | MEMS switches, connector pins | Stable conductivity after 10K insertions |

| Industrial | Pressure switch discs, valve seals | Immune to hydraulic fluid degradation |

| Consumer | Guitar frets, watch mainsprings | Polishes to mirror finish without pitting |

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Products

Phone