C64200 Silicon Aluminum Bronze: Ultimate Wear-Resistant Alloy

(UNS C64200 | ASTM B271 | SAE 68B)

Cu 88-91% · Al 6-8% · Si 2-4% · Fe 1.5-2.5% · Corrosion Warrior · Zero-Maintenance Champion

Product Overview: The Heavy-Duty Performer

Trusted by the U.S. Navy since 1972 for submarine shafting, C64200 combines aluminum bronze’s strength with silicon’s corrosion resistance. This alloy withstands 500°F (260°C) steam environments and 30-knot seawater flow while delivering 2× the fatigue life of nickel-aluminum bronzes. Certified to ASTM B271, MIL-B-24480, and ASME SB150, it powers critical systems in nuclear reactors, desalination plants, and offshore platforms exposed to extreme abrasion and chemical attack.

Technical Parameters

| Property | C64200 Value | C63000 Bronze | 316 Stainless |

|---|

| Composition | Cu 88-91% | Cu 82% | Fe 70% |

| Al 6-8% | Al 10% | Cr 18% |

| Tensile Strength | 760 MPa | 650 MPa | 580 MPa |

| Corrosion Rate (SW) | 0.003 mm/yr | 0.008 mm/yr | 0.002 mm/yr |

| Wear Resistance | 0.15 mm³ loss | 0.35 mm³ | 0.25 mm³ |

| Thermal Conductivity | 52 W/m·K | 45 W/m·K | 16 W/m·K |

| Max Service Temp | 425°C (800°F) | 290°C | 800°C |

Certifications: ASTM B271 Class 4. NACE MR0175. ASME Boiler Code, DNV GL OS F101

Top 4 Competitive Advantages

Extreme Wear Resistance

58% lower wear rate than C95400 (ASTM G65)

Acid/Caustic Immunity

Withstands pH 2-12 at 150°C without pitting

Fatigue Strength

340 MPa at 10⁸ cycles (2× C63000)

Zero Lubrication

Self-lubricating silicon films reduce friction by 40%

Critical Performance Features

Biofouling Resistance: 90% less barnacle adhesion vs. copper alloys

Cavitation Erosion Defense: 4× longer life than CA104 bronze

Non-Sparking: ATEX/IECEx Zone 0 certified

Thermal Shock Tolerance: Withstands 250°C/minute gradients

Non-Magnetic: Permeability <1.02 μ

Advanced Manufacturing Process

1 Vacuum Arc Remelting

Electrolytic Cu + Aerospace-grade Al/Si @ 1250°C

2 Hot Forging

850°C @ 60% reduction → directional grain flow

3 Solution Treatment

780°C × 4hr → β-phase homogenization

4 Aging

480°C × 8hr → precipitate κ-phase hardening

5 Quality Assurance

100% UT + hardness mapping + spectrographic analysis

Core Applications

| Industry | Critical Components | Standards |

|---|

| Marine Engineering | Propeller shafts, stern tubes | ABS 3. Lloyds LR 2.4 |

| Power Generation | Desalination pump impellers, valves | ASME B73.1. API 610 |

| Chemical Processing | Reactor agitators, acid transfer lines | ASTM A276. NACE MR0103 |

| Aerospace | Landing gear bushings, actuators | AMS 4890. MIL-B-24480 |

| Mining | Slurry pump volutes, dredge components | ISO 13359. AS 2417 |

Top Search Keywords:

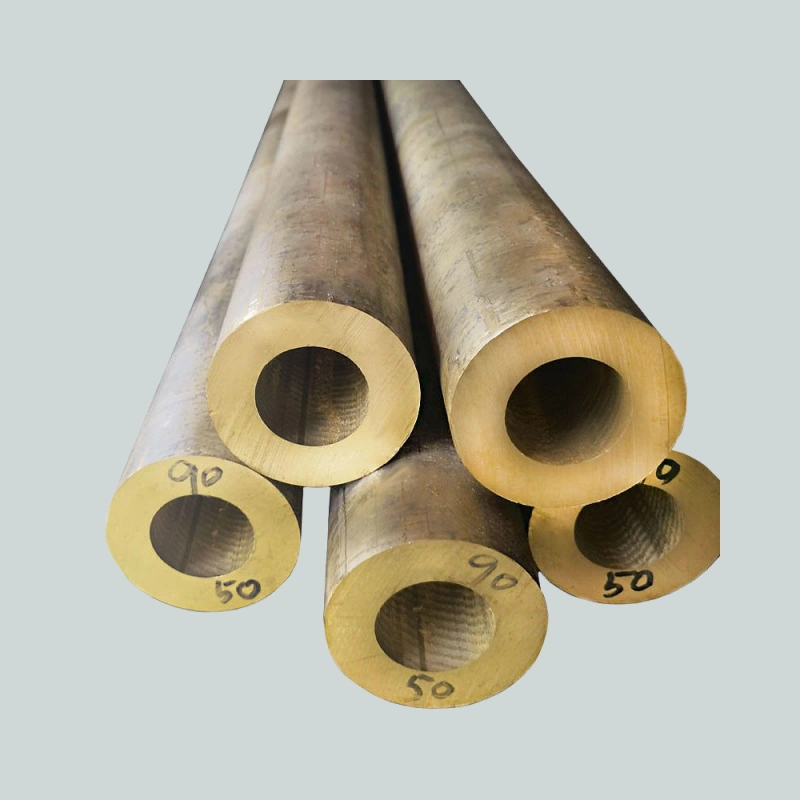

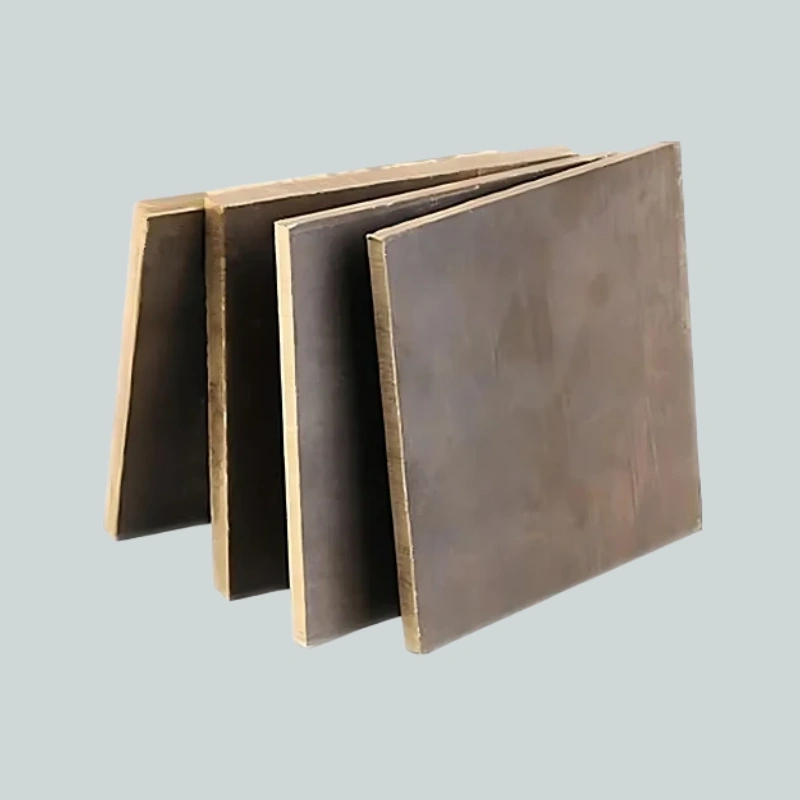

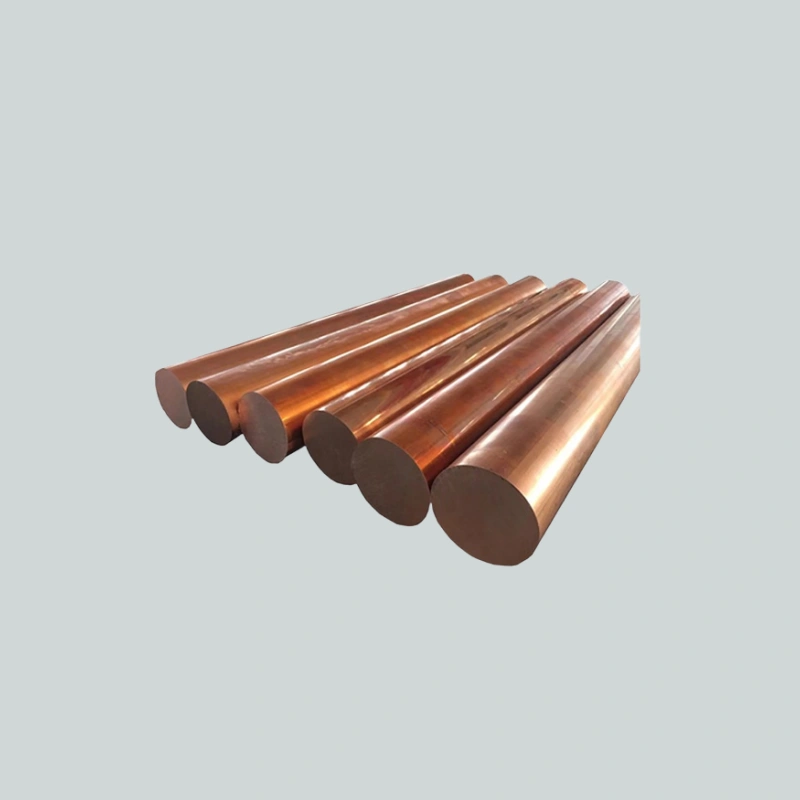

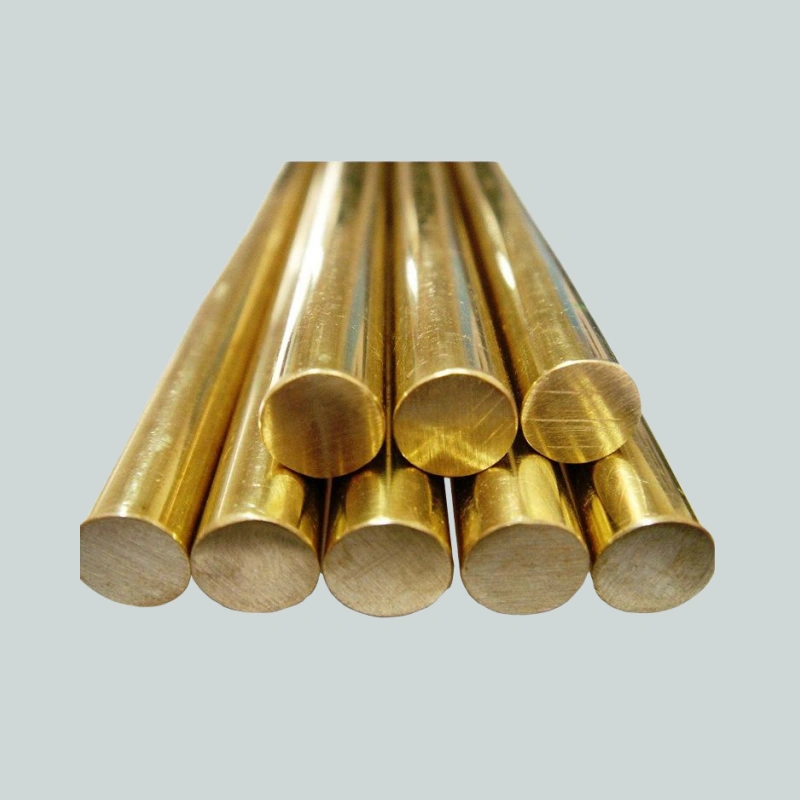

C64200 bronze bushings | Aluminum bronze seawater pumps | Non-sparking C64200 | ASTM B271 rods

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.