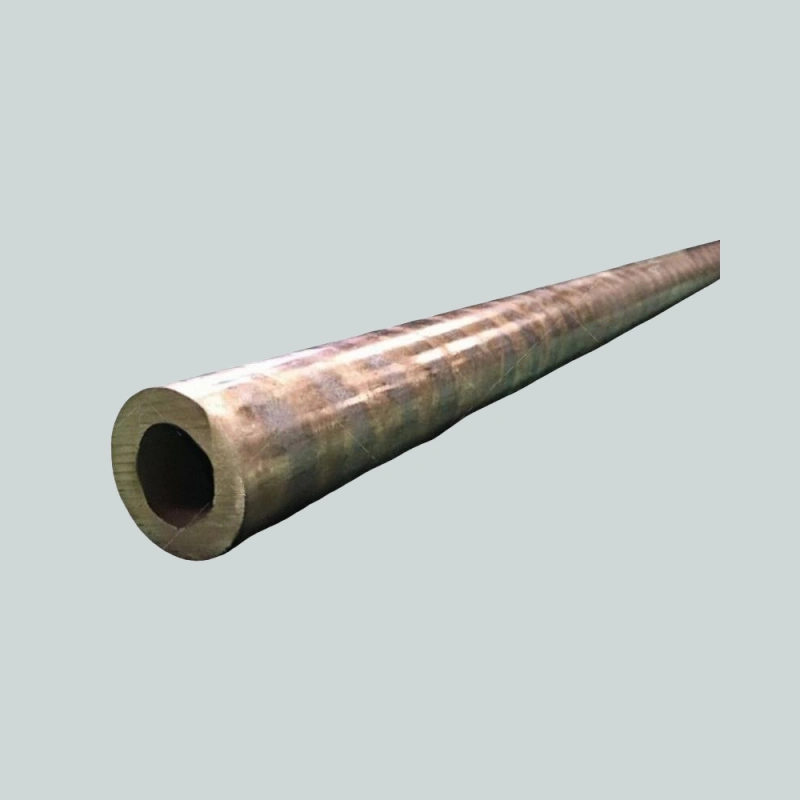

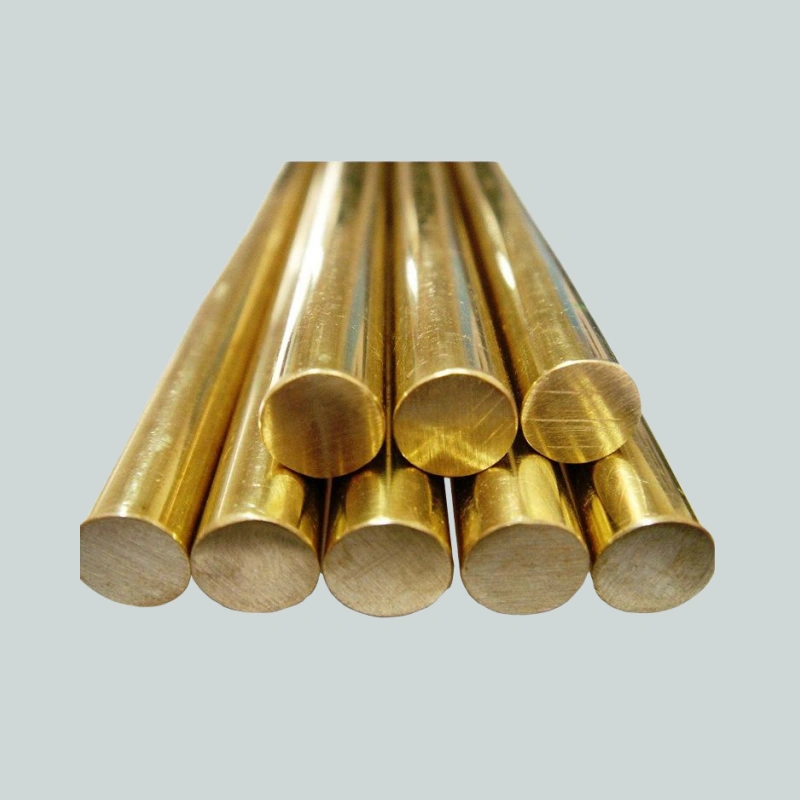

C63600 Silicon Aluminum Bronze: The Precision Engineer's Choice

(UNS C63600 | ASTM B271 | SAE 65B)

Cu 91-94% · Al 5.5-6.5% · Si 1.5-2.5% · Fe ≤0.25% · Machining Master · Corrosion Defender

Product Overview: The Versatile Performer

Developed for U.S. Navy shipbuilding in the 1960s, C63600 strikes the ideal balance between silicon bronze’s corrosion resistance and aluminum bronze’s strength. With 35% higher machinability than standard bronzes and exceptional thermal conductivity (59 W/m·K), it excels in complex marine fittings, steam systems, and precision bushings. Certified to ASTM B271, ASME SB150, and MIL-C-22262, this alloy withstands 400°F (204°C) continuous service while resisting saltwater corrosion at flow rates up to 15 knots.

Technical Parameters

| Property | C63600 Value | C63000 Bronze | 316 Stainless |

|---|

| Composition | Cu 91-94% | Cu 82% | Fe 70% |

| Al 5.5-6.5% | Al 10% | Cr 18% |

| Tensile Strength | 620 MPa | 650 MPa | 580 MPa |

| Machinability Rating | 85% (free-cutting) | 20% | 45% |

| Thermal Conductivity | 59 W/m·K | 45 W/m·K | 16 W/m·K |

| Corrosion Rate (SW) | 0.005 mm/yr | 0.008 mm/yr | 0.002 mm/yr |

| Max Service Temp | 400°C (750°F) | 290°C | 800°C |

|

|

|

|

Certifications: ASTM B271 Class 2. NACE MR0175. AMS 4890. EN 1982

Top 4 Competitive Advantages

Unmatched Machinability

4× faster machining than C63000 (per ASTM E618)

Thermal Management

3.7× better heat dissipation than stainless steel

Marine-Grade Durability

15+ year service life in splash zones

Cost Efficiency

30% lower part cost vs. C64200 due to reduced tool wear

Critical Performance Features

Stress Corrosion Immunity: 0 failures in 5.000-hr ammonia vapor tests

Non-Galling: Silicon-rich films reduce friction by 35%

Weldability: Autogenous TIG welding without preheat

Biofouling Resistance: 70% less marine growth vs. copper alloys

Non-Sparking: ATEX Zone 2 certified

Precision Manufacturing Process

1 Controlled Atmosphere Melting

Oxygen-free Cu + Al/Si additives @ 1100°C under nitrogen

2 Continuous Casting

Electromagnetic stirring → uniform fine-grain structure

3 Hot Extrusion

750°C @ 40:1 ratio → optimized mechanical properties

4 Cold Drawing

30% reduction → enhanced surface finish

5 Quality Validation

100% eddy current testing + ASTM E8/E18 mechanical tests

Core Applications

| Industry | Critical Components | Standards |

|---|

| Marine Engineering | Seawater valves, pump shafts | ABS 3. Lloyds LR 2.4 |

| Power Generation | Steam turbine bushings, heat exchangers | ASME B31.1. API 610 |

| Automotive | Transmission synchronizers, bearings | SAE J461. ISO 4381 |

| Industrial Machinery | Hydraulic cylinders, gear components | ISO 4378-1. DIN 1709 |

| Chemical Processing | Acid transfer fittings, valve stems | NACE MR0103. ASME B16 |

Top Search Keywords:

C63600 bronze bushings | Machinable silicon bronze | Marine bronze valves | ASTM B271 rods

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.