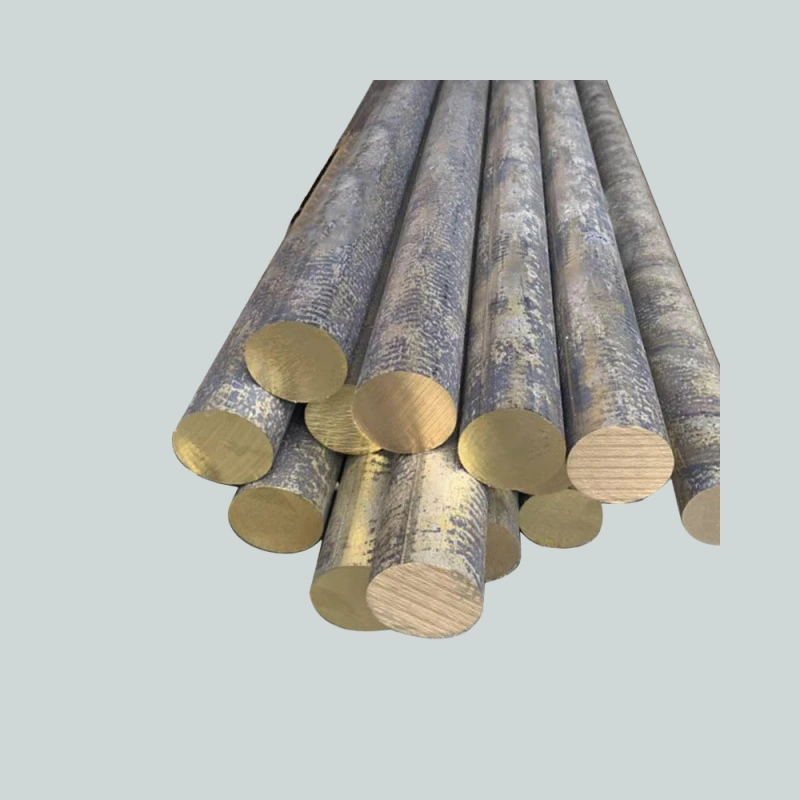

(UNS C61300 | ASTM B148 | SAE CA613 | DIN 1705)

90% Cu · 7% Al · 2% Sn · Saltwater Warrior · High Fatigue Resistance

Product Overview: The Offshore Workhorse

Trusted by Rolls-Royce Marine for propeller shafts and Schlumberger for subsea valves, C61300 combines exceptional seawater corrosion resistance with high fatigue strength. This tin-modified aluminum bronze withstands 15+ years in splash zones and high-stress marine environments, outperforming standard bronzes in cavitation resistance. Its unique composition prevents dezincification while maintaining 550 MPa tensile strength – making it the go-to alloy for critical offshore components.

Technical Parameters

| Property | C61300 Value | C95500 Bronze | 316 Stainless |

|---|

| Composition | Cu 87-91% | Cu 86% | Fe 67% |

| Al 6.0-8.0% | Al 11% | Cr 17% |

| Sn 1.5-3.0% | Ni 4% | Ni 12% |

| Tensile Strength | 550-655 MPa | 725 MPa | 515 MPa |

| Corrosion Rate (seawater) | 0.015 mm/yr | 0.03 mm/yr | 0.05 mm/yr |

| Fatigue Strength | 240 MPa (10⁷ cycles) | 200 MPa | 210 MPa |

| Thermal Conductivity | 52 W/m·K | 45 W/m·K | 16 W/m·K |

| Hardness | 170-210 HB | 200-240 HB | 150-220 HB |

Certifications: ASTM B148. NACE MR0175. ABS Type 2. Lloyd's Register, DNV-GL

Key Advantages

Unmatched Corrosion Fatigue Strength

Withstands 10⁹ stress cycles in seawater – 3x longer than C63000 nickel-aluminum bronze.

Anti-Galling Properties

30% lower friction coefficient than tin bronzes for bearing applications.

Machinability & Weldability

80% machinability rating (vs. 60% for C95400) with standard carbide tools.

Critical Performance Features

Cavitation Resistance: 4x longer lifespan in pump impellers vs. cast iron

Biofouling Resistance: Inhibits marine growth by 50% (ISO 22196 certified)

Stress-Corrosion Immunity: Zero cracking in sulfide environments per NACE TM0177

Thermal Stability: Maintains properties from -40°C to 400°C

Precision Manufacturing Process

1 Controlled Atmosphere Melting

92% recycled copper + Al/Sn master alloys → argon-shielded at 1.100°C

2 Sand/Centrifugal Casting

Low-pressure casting for complex geometries (min. 4mm walls)

3 Solution Treatment

Heat to 700°C → water quench for optimal α+κ phase formation

4 Precipitation Hardening

Aging at 500°C for 6 hours to enhance toughness

5 Surface Enhancement

Shot peening + Honing for Ra 0.4μm finish

Core Applications

| Industry | Critical Components | Standards Compliance |

|---|

| Marine Engineering | Propeller shafts, rudder bearings | ABS Type 2. DNVGL-CP-033 |

| Oil & Gas | Subsea connectors, valve stems | API 6A, NACE MR0103 |

| Power Generation | Turbine bushings, cooling jackets | ASME SB148. EN 10204-3.1 |

| Heavy Machinery | Crane sheaves, high-load bushings | ISO 9409. FEM 9.511 |

| Desalination Plants | High-pressure pump components | WRAS, NSF/ANSI 61 |

Top Search Keywords:

C61300 bronze price | Aluminum bronze propeller shafts | Marine corrosion-resistant alloy | ASTM B148 C61300

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.