What are the popular grades of copper?

14 August 2025 | By Xiangrui Steel | Volume 0

Copper is an important metallic material that is widely used in multiple industries due to its excellent electrical conductivity, thermal conductivity and corrosion resistance. Among the numerous grades of copper, some have become popular choices due to their special properties and wide applications. The following will provide a detailed introduction to several common types of copper plates, including their composition, characteristics and application fields.

1. C11000 (Pure copper)

C11000 is the most common pure copper grade, with a copper content of over 99.9%. It has excellent electrical conductivity and thermal conductivity, with an electrical conductivity as high as 101% IACS (International Electrical Conductivity Standard). The excellent formability and weldability of C11000 make it widely used in the electrical industry, such as in cables, joints and motor windings. Due to its excellent corrosion resistance, C11000 is also used in the manufacture of various consumer goods, such as kitchenware and decorations.

2. C10200 (Oxygen-free copper)

C10200 is an oxygen-free copper with a copper content of over 99.9% and an extremely low oxygen content (usually less than 0.001%). This special composition endows C10200 with higher electrical conductivity and better welding performance. C10200 is mainly applied in high-demand electrical equipment and electronic components, such as high-frequency cables and precision electronic components. In addition, it performs exceptionally well in high-temperature and corrosive environments, and thus is also frequently used in the aerospace and military industries.

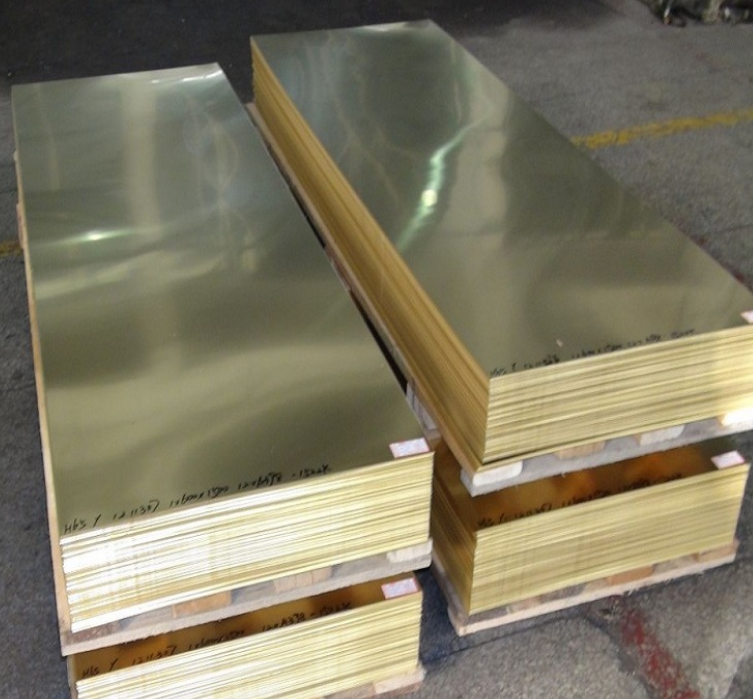

3. C26000 (brass)

C26000 is a brass made of a copper and zinc alloy, with a copper content of approximately 70%. This grade of brass has excellent mechanical properties and corrosion resistance, and is easy to process. C26000 is widely used in the manufacture of valves, pipe fittings, decorative parts and various mechanical components. Due to its elegant golden yellow appearance, the C26000 is also often used in the production of jewelry and ornaments.

4. C28000 (Lead brass)

C28000 is a brass containing lead, typically with a copper content of approximately 60%. The addition of lead significantly improved its processing performance, making it perform outstandingly during cutting operations. C28000 is often used in the manufacture of precision mechanical parts and wear-resistant components, such as gears, bearings and sliders. Although the presence of lead may affect its corrosion resistance, C28000 still holds a place in many industrial applications due to its excellent processing performance.

5. C65500 (Aluminum Bronze)

C65500 is an aluminum bronze with approximately 60% copper content and also contains aluminum and other elements. The addition of aluminium endows it with excellent corrosion resistance and strength, making it suitable for use in Marine environments and high-temperature conditions. C65500 is widely used in ships, Marine engineering and chemical equipment, especially in situations where strength and corrosion resistance are required. In addition, aluminium bronze is also often used to make high-strength tools and mechanical parts.

6. C95400 (Aluminum Bronze)

C95400 is a high-strength aluminum bronze with approximately 80% copper content. It performs well in mechanical properties, featuring excellent wear resistance and impact resistance. C95400 is often used to manufacture high-load mechanical components, such as gears, valves and stamping dies. Due to its excellent wear resistance, this grade of copper has also been widely used in the aerospace and heavy industry fields.

Conclusion

Copper, as an important metallic material, plays a significant role in various industries due to its excellent physical and chemical properties. Popular copper plates such as C11000, C10200, C26000, C28000, C65500 and C95400 each have unique characteristics and a wide range of application scenarios. When choosing copper materials, understanding the composition and properties of different grades will help make appropriate choices based on specific needs, thereby achieving the best usage effect. The diversity and wide application of copper make it indispensable in modern industry and daily life.