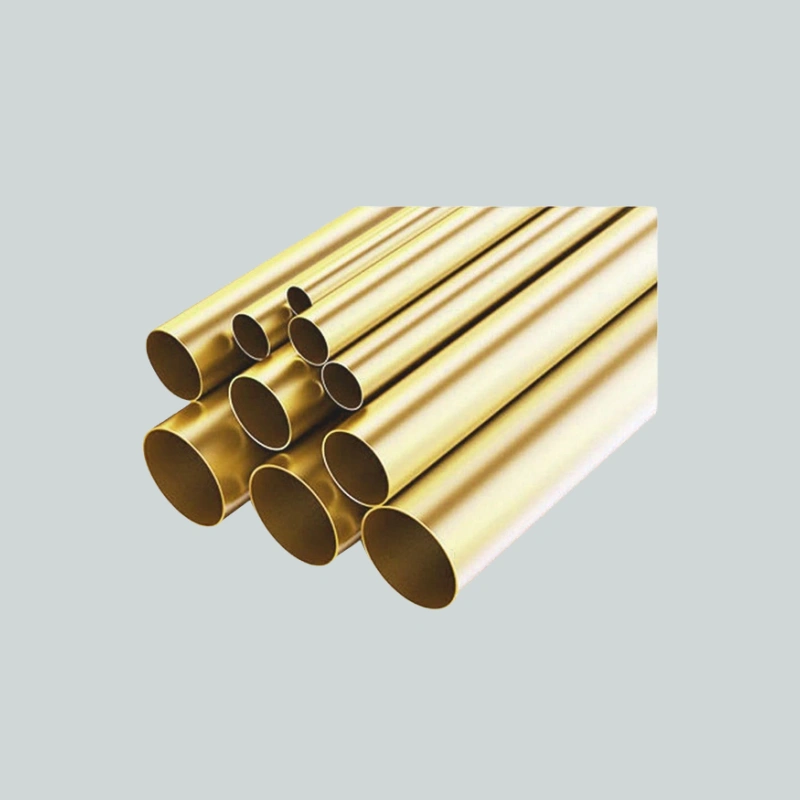

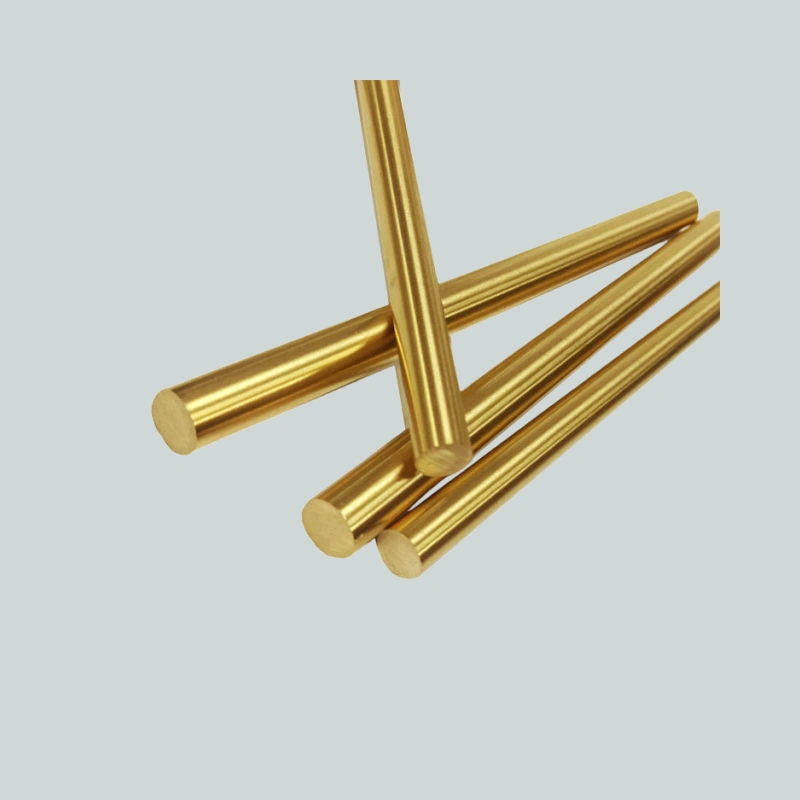

Product Parameters

Alloy Composition: 90% copper, 10% nickel, with trace amounts of iron (0.4-1.0%) and manganese (0.1-0.8%)

Bar Diameter: 6mm to 200mm (custom sizes available upon request)

Length: Standard 3m, 6m, or cut-to-size options

Temper: Annealed (O), quarter-hard (1/4H), half-hard (1/2H), full-hard (H)

Surface Finish: Hot-rolled, cold-drawn, or polished

Mechanical Properties: Tensile strength 340-480 MPa; Elongation 15-45% (varies by temper)

Standards Compliance: ASTM B151. ASME SB151. EN 12449

Product Advantages

Exceptional Corrosion Resistance: Performs reliably in seawater, brackish water, and industrial chemicals, with minimal pitting or crevice corrosion even after decades of use.

Cost-Effective Durability: Offers longer service life than traditional materials, reducing replacement frequency and lifecycle costs.

Excellent Machinability: Easy to cut, drill, and shape with standard tools, minimizing production time and waste.

Good Thermal Conductivity: Efficiently transfers heat, making it suitable for heat exchange applications.

Compatible with Seawater: Naturally resistant to biofouling, eliminating the need for toxic anti-fouling treatments.

Product Features

Low Magnetic Permeability: Ideal for sensitive electronic and navigation equipment near magnetic fields.

Iron Additive: Enhances resistance to impingement corrosion from fast-flowing water.

Uniform Structure: Consistent grain formation throughout the bar ensures predictable performance in any application.

Weldable: Compatible with common welding techniques including TIG and MIG, allowing for strong, durable joins.

Temperature Stability: Maintains mechanical properties in temperatures ranging from -270°C to 200°C.

Product Process

Alloy Melting: Raw materials are melted in controlled-atmosphere furnaces to prevent oxidation and ensure precise composition.

Continuous Casting: Molten alloy is cast into billets with strict temperature control to form a uniform base structure.

Hot Rolling: Billets are rolled to approximate bar dimensions while refining the grain structure.

Cold Drawing: Precision cold drawing achieves final dimensions with tight tolerances (±0.05mm).

Annealing: Controlled heat treatment adjusts hardness and ductility according to temper requirements.

Quality Testing: Each batch undergoes ultrasonic testing, chemical analysis, and mechanical property verification to ensure compliance.

Main Application Fields

Marine Engineering: Ship hulls, seawater intake systems, propeller shafts, and offshore platform components.

Desalination Plants: Brine handling pipes, heat exchanger tubes, and membrane support structures.

Power Generation: Condenser tubes in thermal and nuclear power plants, cooling system components.

Chemical Processing: Piping, valves, and pumps for handling corrosive fluids.

Oil & Gas Industry: Subsea manifolds, wellhead equipment, and offshore pipeline connections.

Water Treatment: Chlorine contact tanks, filtration system components, and water distribution pipes.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.