Product Parameters

Conductor Material: 99.95% pure copper (ETP grade) or 99.7% aluminum (1060/1350 series)

Diameter Range: 0.02mm – 5.0mm (copper); 0.1mm – 6.0mm (aluminum)

Insulation Thickness: 0.005mm – 0.2mm (varies by diameter and insulation class)

Insulation Classes: Class 130 (B), 155 (F), 180 (H), 200 (N) (polyester, polyurethane, polyimide options)

Tensile Strength: Copper ≥ 200 MPa; Aluminum ≥ 85 MPa

Elongation: ≥ 15% (copper); ≥ 12% (aluminum)

Breakdown Voltage: 1.5kV – 15kV (increases with insulation thickness)

Standards Compliance: IEC 60317. NEMA MW 1000. GB/T 6109

Product Advantages

Universal Compatibility: Round shape works seamlessly with all winding machines (horizontal, vertical, automatic), making it ideal for diverse production lines.

Cost-Effective Production: Simple cylindrical design reduces manufacturing complexity, lowering base costs by 15-20% compared to specialty wires.

Proven Reliability: Decades of industry use in standard applications, with well-documented performance in motors, transformers, and coils.

Material Flexibility: Copper provides 98% IACS conductivity for high-efficiency needs; aluminum offers 61% IACS with 30% weight savings.

Insulation Versatility: Multiple enamel options (e.g., polyurethane for solderability, polyimide for high temps) let users match wire to specific needs.

Product Features

Smooth Surface: Enamel coating forms a glossy, uniform finish that reduces friction during winding, minimizing insulation wear.

Consistent Diameter: Tight tolerance (±0.002mm for small wires) ensures even winding tension and predictable performance.

Flexible Handling: Easily bent and shaped (minimum bend radius: 2× diameter for copper, 3× for aluminum) without insulation cracking.

Thermal Shock Resistance: Withstands rapid temperature changes (e.g., -40°C to 180°C) common in industrial environments.

Moisture Resistance: Enamel formulation resists water absorption, maintaining dielectric strength in humid conditions.

Product Process

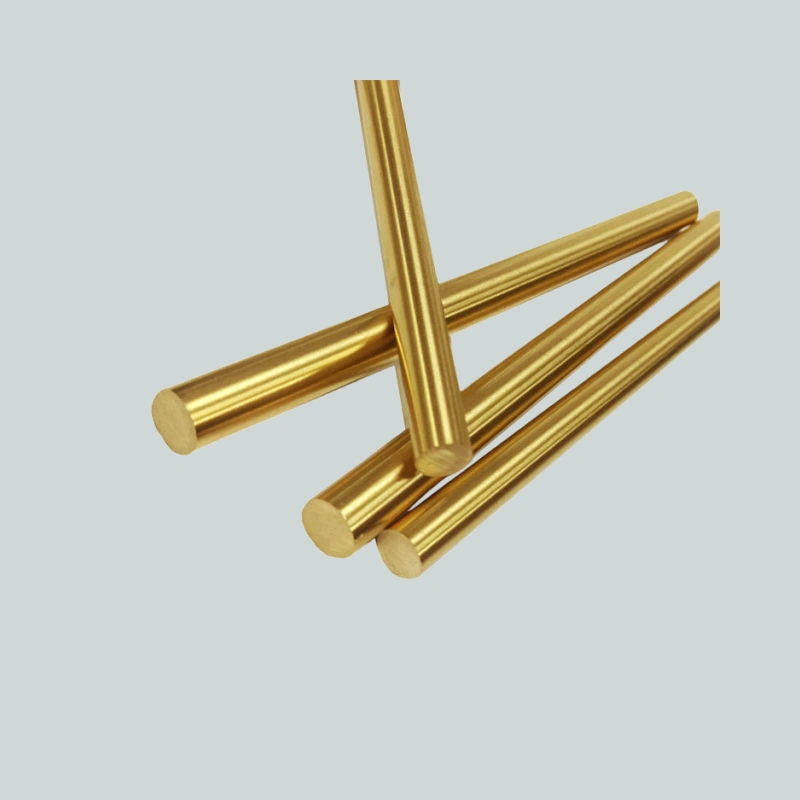

Wire Drawing: Copper/aluminum rods are drawn through dies to achieve precise round diameters, with intermediate annealing for ductility.

Surface Cleaning: Chemical degreasing and pickling remove impurities, ensuring strong enamel adhesion.

Enamel Application: Liquid enamel is applied via die coating (for small diameters) or dipping (for larger sizes), with each layer cured at 300-450°C.

Curing & Cooling: Controlled oven curing forms a hard, flexible insulation layer; air cooling prevents thermal stress.

Quality Testing: Includes diameter checks, breakdown voltage testing, and adhesion tests (enamel must withstand 180° bending without peeling).

Spooling: Wound onto plastic or metal spools (1kg to 50kg capacity) for easy integration into winding processes.

Main Application Fields

Household Appliances: Motors in refrigerators, washing machines, and fans, where standard performance meets cost needs.

Automotive Electricals: Starter motors, window regulators, and sensor coils, using copper for conductivity or aluminum for weight savings.

Electronics: Transformers, inductors, and solenoids in TVs, computers, and power supplies.

Industrial Equipment: Small to medium motors, pumps, and control systems requiring reliable, affordable winding wire.

Renewable Energy: Solar panel inverters and small wind turbine generators, leveraging cost-effective aluminum options.

Consumer Electronics: Voice coils in speakers, micro-motors in cameras, and charging coils in wireless devices.

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.