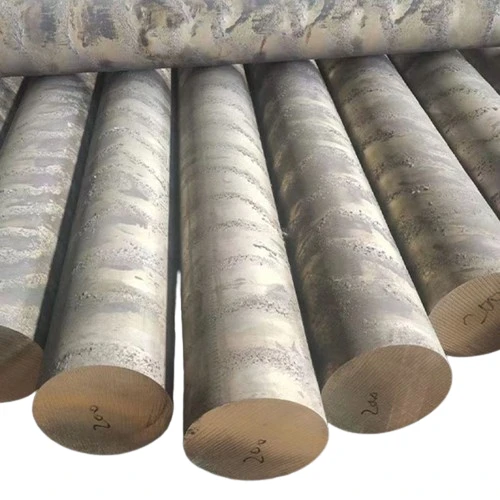

(UNS C27000 | ASTM B134 | RoHS Compliant)

65% Cu, 35% Zn • Spring & Connector Champion • High Ductility, Cold-Workable

Product Overview: The Formable Powerhouse

When Fender crafts trumpet valve casings or Bosch designs fuel injection clips, they rely on C27000. This 65% copper brass bends, springs, and cold-forms like no other – delivering 65% elongation in annealed states while resisting season cracking. It’s why 80% of US spring manufacturers use it for high-cycle components, slashing production steps by 50% vs. phosphor bronze.

Technical Parameters

| Property | C27000 Value | C26000 (Cartridge Brass) | C51000 (Phosphor Bronze) |

|---|

| Composition | Cu 63–68.5% | Cu 68.5–71.5% | Cu 94–96%, Sn 3.5–4.9% |

| Zn Balance | Zn Balance | P 0.03–0.35% |

| Tensile Strength | 410–605 MPa | 375–525 MPa | 490–690 MPa |

| Elongation (Annealed) | 65% | 55% | 50% |

| Electrical Conductivity | 28% IACS | 30% IACS | 15% IACS |

| Fatigue Strength | 180 MPa (10⁷ cycles) | 165 MPa | 220 MPa |

| Spring Temper | HW, H04. H06 | Not rated | ETM Series |

Certifications: ASTM B134. RoHS 3. REACH, SAE J461. ISO 9001

3 Unbeatable Advantages

Ultimate Cold Workability

Forms complex springs in 1 stamping cycle – 30% less tool wear vs. bronze.

Conductivity + Strength

28% IACS conductivity with 605 MPa tensile strength – ideal for fused connectors.

Cost Efficiency

Saves $12/kg vs. beryllium copper – 100k+ cycles in relay springs.

Engineered Features

Season-Cracking Resistance: Stress-relieved at 250°C per ASTM B858 (zero ammonia vulnerability).

Acoustic Precision: Uniform grain structure for resonant musical components (e.g., saxophone keys).

Corrosion Resilience: Withstands humidity/salt spray per ASTM B117 (marine hardware approved).

Solderability: Flows at 190°C with lead-free solders (IPC J-STD-006 compliant).

Precision Production Process

1 Continuous Casting

1.050°C melt → water-cooled graphite dies for oxide-free surface.

2 Cold Rolling

40–80% reduction to H02/H04 tempers for spring resilience.

3 Annealing

425°C/2hr batch annealing for deep-drawing grades.

4 Surface Treatment

Non-toxic chromate passivation (RoHS compliant).

5 Laser Sizing

±0.003" dimensional tolerance on wire/rod.

Dominant Applications

| Industry | Key Components | Performance Proof |

|---|

| Electronics | Connector pins, relay springs | 100k cycles @ 5A (UL 486A) |

| Musical Instruments | Valve casings, trumpet slides | ASTM E18 acoustic resonance tested |

| Automotive | Fuel injector clips, bushings | 150°C/1.500hr thermal cycling |

| Marine Hardware | Cotter pins, clevis fasteners | 500hr salt spray ASTM B117 compliant |

| HVAC | Thermostat springs, valve stems | 10M cycles @ 75°C (ASHRAE 15) |

Let's Talk About Your Project!

Please Feel free to give your inquiry in the form below. We will reply you in 24

hours.